Maximizing Your Warehouse Footprint: A Step-by-Step Guide to Safe Mezzanine Floor Construction

If you’re a business owner in Oklahoma City (OKC) staring up at unused ceiling height in your warehouse, manufacturing plant, or retail space, you’re looking at untapped potential. Expanding your operational space used to mean moving to a bigger, more expensive facility. Not anymore. The smart, cost-effective solution is building up, not out, with a custom-engineered mezzanine floor.

As experienced metal construction company experts in OKC, we know that mezzanines are one of the most powerful tools for space optimization. They can double your usable floor area quickly and efficiently. But installing one isn’t a DIY job; it requires the skill and precision of professional mezzanine floor contractors.

This comprehensive guide walks you through the entire process, ensuring your investment is safe, compliant, and maximizes your operational efficiency.

What Is a Mezzanine Floor and Why Is It the Smartest Investment for Oklahoma Businesses?

A mezzanine floor is an intermediate floor installed between the main floors of a building, usually resting on supporting columns and beams and designed to be partially open to the floor below. Unlike a permanent second story, a mezzanine is a semi-permanent structural addition that maximizes vertical space, often without requiring major structural changes to the primary building or extensive permitting delays.

For businesses in Oklahoma, where the cost of commercial real estate continues to rise, a mezzanine offers immediate financial and operational benefits.

The Economic and Operational Advantages of Mezzanines

When you choose a professional team of mezzanine installers, you unlock powerful benefits:

- Cost Efficiency: Installing a mezzanine is significantly cheaper and faster than constructing a conventional building addition or relocating your business entirely. You get twice the space for a fraction of the cost.

- Flexibility and Customization: Mezzanines are truly versatile. They can be used for bulk storage, creating dedicated office space for supervisors, setting up new assembly lines, accommodating automated retrieval systems, or developing retail display areas. This level of versatility ensures a rapid return on investment.

- Increased Property Value: A professionally installed, structurally sound mezzanine, engineered by structural steel contractors, adds substantial, quantifiable value to your commercial property.

- Minimal Disruption: The installation process is often designed to work around your existing operations, minimizing downtime.

Understanding the Types: Free-Standing vs. Structural Mezzanines

The type you choose depends heavily on your intended use and load requirements:

- Free-Standing (Structural): These systems use steel columns anchored to the floor slab, creating an entirely independent structure. They are highly flexible, relatively easy to dismantle and relocate, and are the most common choice for heavy industrial or high-capacity office use. They rely on detailed custom metal fabrication for their components.

- Rack or Shelving Supported: These mezzanines are built directly on top of heavy-duty storage racks. While effective for storage, they are far less flexible and may not be suitable for high foot traffic or office space.

For commercial applications where safety and heavy loads are a concern, working with contractors metal works who specialize in the free-standing, structural option is almost always the better choice.

Step One: Comprehensive Planning and Site Preparation

Before a single piece of steel is moved, the planning stage dictates the success and safety of your project. This is where your chosen metal construction company earns its reputation.

Calculating Load Capacity and Clearances

The first and most critical step is a thorough site survey. Our team uses advanced engineering to determine:

- Clearance: The minimum height required above and below the mezzanine. OSHA requires specific minimum clearances, usually around 7 feet.

- Load Bearing: What is the load capacity of your existing concrete slab? A structural mezzanine transfers its weight through the columns, so the slab must be able to handle the significant point loads.

- Intended Use Load: The floor itself must be designed for its purpose. An office mezzanine requires less load capacity than one used for heavy machinery storage or high-volume pallet jack traffic. This calculation is a primary function of the structural steel contractor’s engineering team.

Navigating Oklahoma City Building Codes, Permits, and Fire Safety

Any reputable metal building contractors near me will emphasize that mezzanines are regulated structures, especially in commercial settings. They are subject to local OKC building codes (which often align with IBC and NFPA standards). Key considerations include:

- Fire Suppression: Depending on the size, use, and location of the mezzanine, you will likely need to extend your sprinkler system. Bar grating flooring is sometimes chosen specifically because it allows water from existing sprinklers to pass through.

- Emergency Exits: You must have compliant access points and means of egress. This often includes specific requirements for stair width, handrail height, and the distance to the nearest emergency exit.

- Seismic/Wind Loads: Oklahoma is subject to unique weather conditions. The structural design must account for local seismic codes and high wind loads to ensure the structure’s integrity—a specialty of expert steel contractors.

Choosing a metal construction company familiar with Oklahoma City’s specific requirements is non-negotiable for project safety and timely approval.

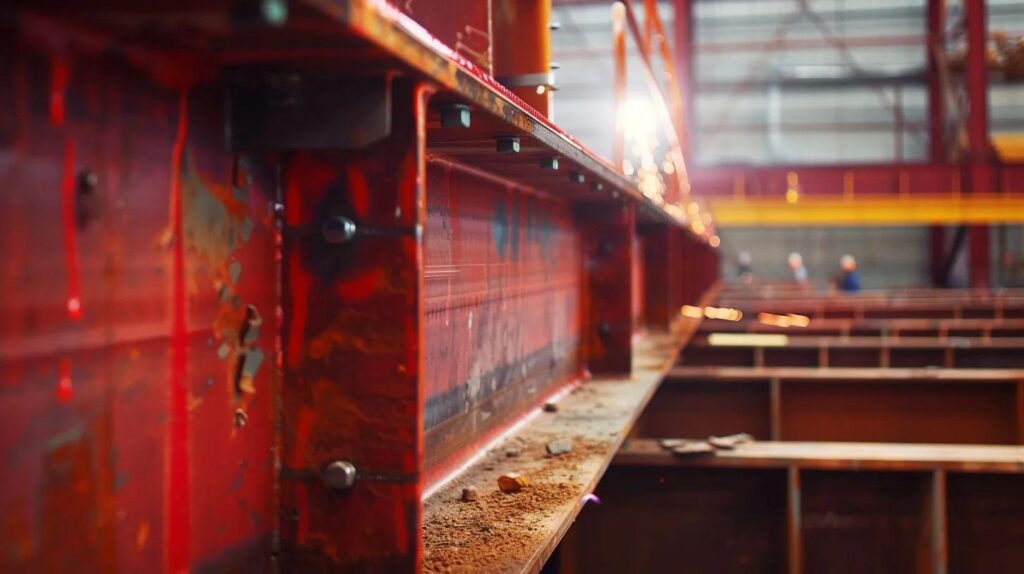

Step Two: Structural Steel Erection and Framework

Once the design is approved and permits are in hand, the physical build begins. This is where the heavy lifting and precise structural steelwork contractors expertise come into play.

Precision Installation by Structural Steel Contractors

The process starts by securing the base plates and support columns.

- Column Installation: The columns must be precisely positioned and anchored to the floor using heavy-duty bolts. The layout must be accurate to within a fraction of an inch to ensure the entire structure is level and plumb.

- Beam Erection: Primary and secondary horizontal beams (often referred to as joists and purlins) are carefully lifted and bolted to the tops of the columns. These beams form the essential structural grid that supports the decking and transfers the load to the ground.

- Red Iron and Structural Steel: High-grade structural steel, or red iron, is the material of choice for its strength and durability. Whether you are building a small platform or a massive multi-level mezzanine, the quality of the steel and the engineering behind its assembly directly impact the structure’s longevity and safety. This is why specialized structural steel contractors are required.

The Critical Role of Welding and Onsite Fabrication

While many mezzanines are bolted, the final structural stability and the addition of custom features often require professional welding. This is particularly true for integrating the mezzanine into an existing structure or adding non-standard components.

Skilled welders in okc are essential for this phase. Sometimes, a component needs adjustment on the fly, or a highly specific connection point is required. This is where on-site expertise matters. Relying on specialized tools for mobile fabrication means that adjustments to items like custom guardrails, stair stringers, or reinforcing brackets can be made instantly, speeding up the build time and ensuring maximum precision. A professional crew will use specific welding techniques to maintain the integrity of the steel without compromising its pre-engineered specifications.

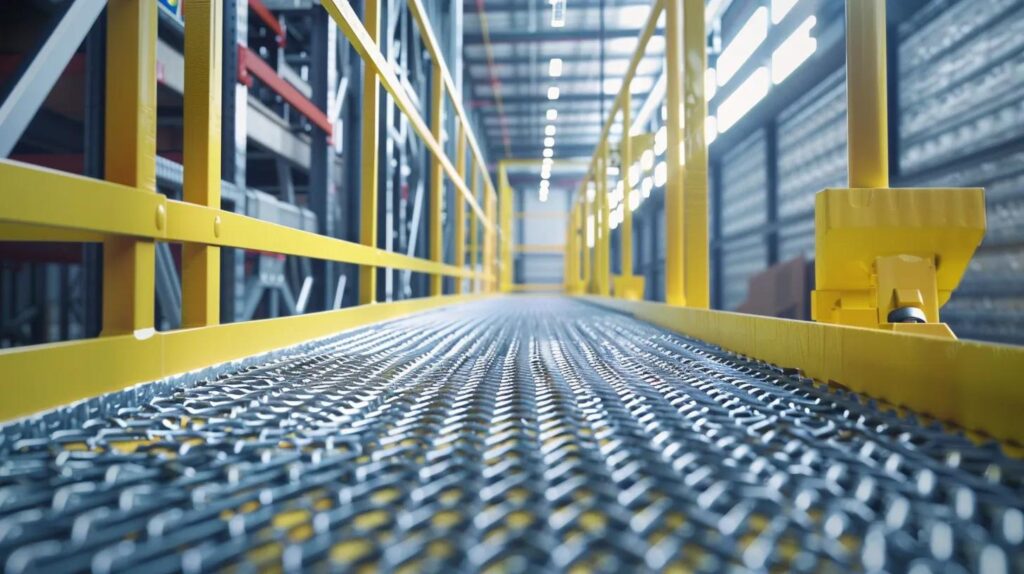

Step Three: Selecting and Installing the Right Decking and Safety Features

The floor decking is the surface you’ll walk and work on, and the safety features are what protect your employees and assets.

Choosing Your Flooring: ResinDek, Bar Grating, or Solid Steel Deck?

The environment and use of the mezzanine will dictate the best flooring choice:

- ResinDek: A high-performance engineered wood flooring. It’s ideal for office areas, light manufacturing, and warehouse applications that see heavy foot traffic or pallet jack use. It’s durable, smooth, and handles high point loads well.

- Bar Grating: A steel grid that allows light, air, and sprinkler water to pass through. It’s perfect for industrial environments that need ventilation or when fire suppression requirements mandate water flow to the lower level. However, it’s not suitable for rolling heavy equipment.

- Solid Steel Plate: Also known as diamond plate or chequer plate, this option is extremely durable and often used in wet environments, heavy-duty manufacturing areas, or facilities that require extreme cleanliness (like food and beverage plants). For these solutions, you need precise sheet metal fabrication capabilities.

Guardrails, Handrails, and Access Points: Safety is Non-Negotiable

Regardless of the flooring, the safety perimeter must meet strict code requirements. Your mezzanine floor contractors must install industrial-grade guardrails and safety handrails that are load-tested and engineered to withstand lateral forces.

- Guardrails: Must be installed along any open edges and be designed to protect personnel from falls.

- Handrails: Must be installed on all staircases and access ladders to aid stability.

- Access Gates: If you are using forklifts or pallet jacks to load inventory, an approved lift-out or slide gate is essential. These gates must lock and be secured to the structure to prevent fall hazards when materials are being moved.

A professional custom metal and fabrication team can design railings and access points that not only meet code but also integrate seamlessly with your facility’s operational flow.

Beyond Installation: Maintenance and the Power of Mobile Welding

A mezzanine floor is a long-term investment that requires routine care to maintain its structural integrity.

Essential Routine Safety Checks and Inspections

Even the best-built structure needs periodic inspection. You should conduct annual checks for:

- Corrosion: Especially in humid or chemical environments.

- Bolt Integrity: Vibration from machinery can loosen bolts over time.

- Column Damage: Impacts from forklifts are a common hazard.

- Load Distribution: Ensuring employees are not overloading sections beyond their rated capacity.

When to Call a Mobile Welding Service Near Me for Repairs

For fast, efficient structural repairs, a mobile welding company is an invaluable resource. If you notice a cracked weld, a bent column, or a damaged handrail, immediate attention is crucial. Waiting for an off-site shop to handle the repair can lead to long downtime.

A reliable mobile welding service near me can dispatch certified professionals with fully equipped trucks right to your location in Oklahoma City, providing onsite welding services for immediate, durable fixes. This service is also often used for installing other quick-maintenance items around your facility, such as security bollards in construction zones or adding anchor points for machinery.

Utilizing pre engineered metal building contractors near me that also offer robust mobile services ensures you have a single, trusted partner for both large-scale projects and urgent repairs.

Frequently Asked Questions (FAQs) About Mezzanine Construction

Q: Are mezzanines considered permanent structures for tax purposes? A: Typically, a free-standing, bolted mezzanine system is often classified as capital equipment rather than a permanent structural addition, which can provide favorable depreciation benefits. However, local regulations vary, so we always advise consulting with your CPA or tax professional regarding your specific installation by mezzanine installers.

Q: How long does the average mezzanine installation take? A: The duration varies depending on the size and complexity (e.g., integrating sprinkler systems). Generally, a standard structural mezzanine for a large warehouse can be installed by experienced mezzanine floor contractors within 4 to 8 weeks from the final design approval, with minimal disruption to your daily operations.

Q: Can a mezzanine be moved if we relocate our business? A: Yes, one of the key benefits of a structural, free-standing mezzanine is its modular design. It can be fully disassembled, moved, and reinstalled in your new location, making it a truly portable and long-term asset.

Q: What is the most common use for a mezzanine in an Oklahoma City commercial space? A: The most common uses are extra warehouse storage space, creating office suites or meeting rooms above the production floor, or setting up dedicated packaging/assembly areas. The possibilities are limited only by the initial design of the metal fabrication custom components.

Frequently Asked Questions (FAQs) About Metal Contractors

Q: What is the primary service Metal Contractors provides? A: Metal Contractors is a leading metal construction company in Oklahoma City providing comprehensive services in structural steel construction, custom metal fabrication, professional welding, and the installation of specialized products like mezzanines, awnings oklahoma city, railings, and bollards for commercial and residential clients.

Q: Does Metal Contractors only work on large commercial projects? A: No. While we are equipped to handle large-scale structural steel and industrial fabrication, we also provide expert services for smaller, custom jobs, including residential custom metal fabrication near me, handrail installation, and emergency mobile welding service near me for all types of metal repair and fabrication needs.

Q: How does Metal Contractors ensure the quality of its structural work? A: Quality is maintained through a combination of using high-grade materials (steel, aluminum, stainless steel), employing certified welders, adhering strictly to AISC/AWS standards, and maintaining clear communication and rigorous quality checks throughout every stage of the project, from sheet metal fabrication design to final installation.

Q: Can Metal Contractors assist with the design and permitting process? A: Yes. We offer comprehensive, end-to-end services. Our experienced in-house design and engineering team works closely with clients to create detailed plans that meet all functional requirements while ensuring full compliance with local OKC building codes and assisting with necessary permits.

Meet the Experts at Metal Contractors (About Us)

Metal Contractors is proud to be Oklahoma City’s premier choice for dependable, high-quality metal construction company and custom metal fabrication services.

Since our inception, our mission has been to provide superior craftsmanship and engineering excellence, turning complex challenges into robust, reliable structural solutions. We operate a state-of-the-art facility staffed by highly trained and certified professionals, including AWS (American Welding Society) certified welders in okc and experienced structural engineers.

Our leadership team possesses decades of combined experience in complex structural steel contractors projects, ensuring that every weld, every bolt, and every custom-fabricated component meets the highest standards of safety and quality.

We believe that being a truly great contractor means being a partner—one who prioritizes safety, transparency, and effective communication from the initial concept to the final inspection. Whether we are fabricating specialized components in our metal fabrication shops near me or deploying a mobile welding service near me for an emergency repair, our commitment to durability and customer satisfaction remains our unwavering focus. Trust Metal Contractors to build your vision with integrity and expertise.

Building Up, Not Out, in Oklahoma City

A mezzanine floor is more than just an extra level; it’s a strategic move that revitalizes your existing real estate, solves storage and office demands, and future-proofs your operations. The success of this project hinges entirely on choosing the right partner.

When you invest in a mezzanine, you need a team that is not only skilled in metal construction company techniques but is also deeply knowledgeable about Oklahoma City’s building environment. By following this step-by-step guide and partnering with certified mezzanine floor contractors like Metal Contractors, you ensure your new space is safe, fully compliant, and engineered for maximum operational success. Stop looking for a new building—look up, and start building your future today.