Article:

Your Definitive Guide to Choosing the Perfect Metal Sheet for Oklahoma City Projects

Choosing the right metal sheet isn’t just about picking a material; it’s about ensuring your project stands strong against Oklahoma City’s unique climate, looks incredible, and lasts for decades. At Metal Contractors, we know that selecting the perfect metal sheet for your construction or fabrication project hinges on a deep understanding of material properties, precise gauge specifications, the demands of our local environment, and the power of custom fabrication. This guide delivers actionable insights on metal sheet selection, from comparing steel, aluminum, copper, zinc, and specialty alloys to decoding gauge and thickness. You’ll learn how crucial factors like corrosion resistance, tensile strength, cost, and Oklahoma City weather conditions drive smart material choices. Plus, discover how our custom metal fabrication services can streamline your decision, ensuring a flawless outcome. By the end, you’ll know exactly where to source quality sheet metal products in OKC and feel confident requesting a quote or consultation from the experts.

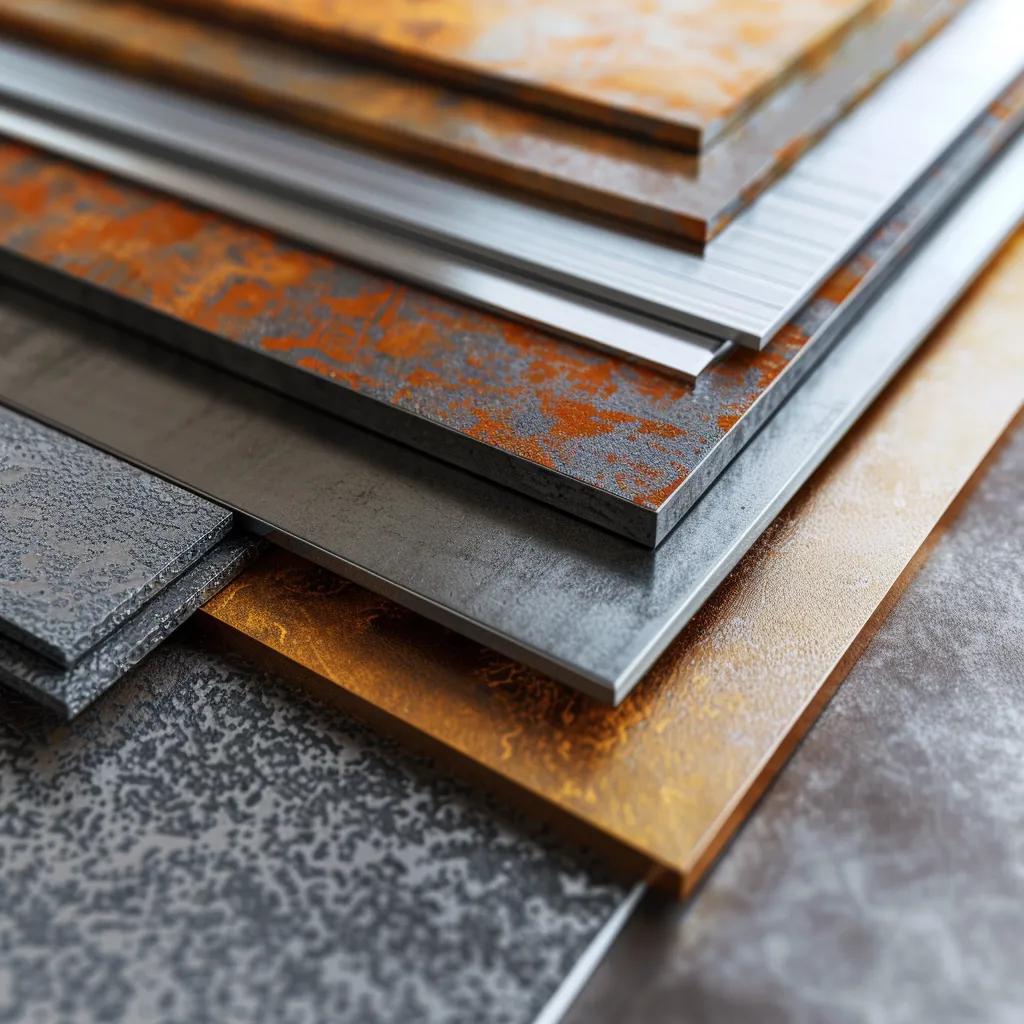

Unpacking Metal Sheet Types and Their Core Properties

Metal sheets are the backbone of modern construction—flat, thin plates of various alloys used extensively in roofing, siding, structural framing, and decorative applications. By expertly leveraging each metal’s unique mechanical strength, corrosion resistance, weight, and conductivity, you achieve optimal project performance and unparalleled durability. For instance, steel delivers robust tensile strength for structural integrity, while aluminum offers lightweight rust protection that stands the test of time. Below, we provide a clear comparison of common sheet metal materials and their key attributes, helping you make an informed choice.

| Metal Type | Attribute | Value/Benefit |

|---|---|---|

| Steel | Tensile Strength | 350–550 MPa (Exceptional load-bearing capacity) |

| Steel | Corrosion Resistance | Moderate (Enhanced with galvanized or Galvalume coatings for OKC weather) |

| Aluminum | Weight | ~2.7 g/cm³ (60% lighter than steel, easing installation) |

| Aluminum | Corrosion Resistance | Excellent (Forms protective oxide layer, ideal for humid climates) |

| Copper | Conductivity | 220–390 S/m (Perfect for electrical and high-end decorative uses) |

| Copper | Aesthetic Appeal | Develops rich, distinctive patina over time, adding character |

| Zinc | Self-Healing Patina | Forms protective carbonate layer to seal minor scratches, ensuring longevity |

| Titanium | Strength-to-Weight | Highest ratio among common alloys, offering superior performance |

This detailed table clarifies how each metal’s unique properties support different applications, making it easier to match the ideal material to your project demands while preparing for precise gauge selection and efficient fabrication processes.

Steel Sheet Metal: The Foundation of Strength and Affordability

Steel sheet metal is our go-to choice for structural and roofing applications, thanks to its unbeatable combination of high tensile strength and cost-effectiveness. Carbon steel delivers robust load-bearing capacity, making it ideal for heavy-duty structures. For environments with moisture or humidity, stainless steel adds superior corrosion resistance. When coated with advanced finishes like Galvalume (a zinc-aluminum alloy) or traditional galvanized finishes, steel sheets can confidently withstand Oklahoma City’s diverse outdoor exposure with minimal maintenance. This remarkable versatility drives its widespread use in both residential and commercial projects across our region.

Aluminum Sheet Metal: Lightweight Durability and Unrivaled Corrosion Resistance

Aluminum sheet metal truly excels at reducing overall structure weight without ever compromising on durability. Its remarkably low density (2.7 g/cm³) not only makes installation significantly easier but also minimizes the load on supporting frameworks, a critical advantage for larger projects. Aluminum naturally forms a thin, protective oxide layer that inherently resists rust, making it an ideal choice for humid conditions or areas prone to moisture. These characteristics translate directly into lower shipping and handling costs for you, along with long-term, reliable performance in siding, roofing, and trim applications that truly last.

Copper Sheet Metal: Elevating Aesthetics and Conductivity

Copper sheet metal stands out as a premium material, celebrated for its exceptional electrical and thermal conductivity, making it perfect for custom gutters, flashing, and exquisite architectural accents. Beyond its functional prowess, copper develops a distinctive, rich greenish patina over time, a natural transformation that dramatically enhances building facades and adds timeless character. While copper’s higher initial cost positions it as a luxury option, its unparalleled longevity and unique, evolving appearance often justify the investment for landmark or high-end decorative projects that demand a statement.

Zinc and Specialty Metal Sheets: Tailored Performance for Unique Demands

Zinc sheet metal offers a remarkable self-healing property: it forms a protective carbonate layer when scratched, ensuring long-term corrosion resistance for roofing and cladding. For projects demanding specialized benefits, titanium and brass step in. Titanium introduces aerospace-grade strength combined with incredible lightness, while brass provides both antimicrobial properties and a classic decorative appeal. While specialty alloys often require advanced fabrication techniques, they deliver precisely tailored performance for high-end, niche applications where standard materials simply won’t suffice.

Mastering Metal Sheet Gauge and Thickness for Your Project's Success

Understanding metal sheet gauge is fundamental to your project’s success. It refers to a numerical scale where a lower gauge number indicates a thicker, more durable sheet. This thickness directly influences structural integrity, overall cost, weight, and the ease of fabrication. For instance, choosing heavier gauge panels means superior resistance to impact and wind load, making them absolutely ideal for roofing in Oklahoma City’s hail-prone regions.

| Gauge | Thickness (inches) | Common Application |

|---|---|---|

| 22 | 0.0312 | Heavy-duty roofing and industrial siding (Maximum durability) |

| 24 | 0.0239 | Residential roofing and trim (Excellent balance of strength and cost) |

| 26 | 0.0187 | Standard roofing, gutters (Widely used, reliable performance) |

| 28 | 0.0149 | Ductwork, light panels (Flexible for interior applications) |

| 30 | 0.0120 | Automotive panels, HVAC components (Precision and formability) |

| 32 | 0.0080 | Appliances, decorative accents (Lightest, for non-structural uses) |

Demystifying the Metal Sheet Gauge System and Its Measurement

The gauge system was established to standardize metal thickness across various industries, ensuring consistency and reliability. Each gauge number corresponds to a precise thickness value, accurately measured with a calibrated micrometer or thickness gauge. It’s important to remember that as the gauge number increases, the thickness of the metal decreases. For example, 26 gauge steel is 0.0187 inches thick, whereas a more robust 22 gauge measures 0.0312 inches. Accurate gauge selection is paramount; it ensures your project not only meets stringent structural code requirements but also exceeds performance expectations for long-term durability.

How Gauge Directly Influences Durability and Cost

Gauge directly impacts durability: a lower gauge (meaning thicker metal) provides superior resistance to dents, wind uplift, and general wear and tear. This is absolutely critical for roofing and exterior siding, especially in areas like Oklahoma City where weather can be unpredictable. However, it’s a balance: thicker sheets naturally cost more per square foot and can increase labor intensity during cutting and bending. Our experts help you balance upfront cost against long-term performance requirements, ensuring you optimize both your budget and the longevity of your investment.

Leveraging a Metal Sheet Gauge Chart for Optimal Thickness Selection

Absolutely, a gauge chart is an invaluable tool that simplifies thickness selection by aligning your project criteria—such as anticipated wind load, span length, and desired finish requirements—with recommended gauges. Reviewing the chart allows you to quickly match the ideal metal thickness to your specific application demands, ensuring you order the correct sheets from the outset and avoid costly rework down the line. It’s a key step in precise project planning.

Key Factors for Selecting the Right Metal Sheets for Your Project

Choosing the right metal sheet involves a comprehensive evaluation of environmental exposure, essential mechanical properties, your budget constraints, and compatibility with fabrication processes. Each of these factors intricately interplays to profoundly affect your project’s performance and its total lifecycle costs.

The Critical Role of Corrosion Resistance in Metal Sheet Selection

Corrosion resistance is a non-negotiable factor; it determines a sheet’s ability to withstand moisture, chemicals, and atmospheric conditions without degrading over time. Materials like aluminum and Galvalume-coated steel truly excel outdoors, offering superior protection, while bare carbon steel may require additional coatings to perform adequately. Prioritizing corrosion resistance significantly reduces future maintenance needs and extends the service life for roofing and cladding, especially vital in Oklahoma City’s variable climate where durability is paramount.

Why Tensile Strength and Durability Are Non-Negotiable for Metal Sheets

Tensile strength reflects a material’s fundamental capacity to bear significant loads before any failure occurs. High-strength sheets resist deformation under stress, a crucial characteristic for structural decks and load-bearing panels that must perform reliably. Beyond raw strength, durable metals also maintain their finish integrity over extended periods, ensuring both lasting visual appeal and unwavering structural safety. Investing in high tensile strength and durability means investing in peace of mind.

Balancing Budget and Cost-Effectiveness in Your Metal Choice

Material cost encompasses more than just the raw sheet price; it includes coatings, fabrication, and installation labor. Lower-cost options like standard galvanized steel are excellent for budget-sensitive projects, while premium alloys deliver specialized benefits at a higher investment. Our team helps you conduct a total-cost-of-ownership analysis, allowing you to weigh upfront savings against long-term performance and maintenance, ensuring you make the most financially sound decision for your project.

Understanding How Fabrication Processes Affect Metal Sheet Compatibility

The techniques for cutting, bending, welding, and forming metal sheets vary significantly by metal type and gauge. Thicker gauges, for instance, may require specialized, heavy-duty equipment, while softer metals like copper and aluminum form with greater ease and flexibility. Early coordination with our expert fabricators ensures that your material choices seamlessly align with your project’s specific fabrication capabilities and precise tolerances, preventing costly delays and ensuring a perfect fit.

Navigating Oklahoma City's Climate: How Environmental Conditions Impact Your Metal Sheet Choice

Oklahoma City experiences a unique blend of weather challenges, including frequent hail, high humidity, significant temperature swings, and occasional severe storms. These specific factors are paramount in influencing the ideal metal type and finish best suited for any outdoor application in our region.

Essential Weather Challenges for Outdoor Metal Sheets in OKC

Our frequent hailstorms demand impact-resistant gauges (e.g., 22 or 24 gauge) to protect your investment. Constant sun exposure and thermal cycling benefit immensely from metals that expand minimally—such as steel with proper coating or specific aluminum alloys. Furthermore, high humidity and the occasional flooding highlight the critical need for superior corrosion-resistant materials or robust protective sealants. We understand these challenges intimately and guide you to the right solutions.

Ideal Metal Sheets for Residential Roofing in Oklahoma City

For residential roofs in OKC, Galvalume and galvanized steel at 26 gauge offer an ideal blend of strength, superior corrosion protection, and cost-effectiveness. Aluminum roofing provides exceptional rust resistance and lightweight installation, though it comes with a higher material cost. Both options are expertly chosen to handle hail impact and thermal expansion effectively, ensuring your home is protected for decades. Our team specializes in these durable solutions.

Optimal Metal Sheets for Commercial Siding and Cladding in Oklahoma City

Commercial projects in Oklahoma City often require large-format panels, typically in 24 or 22 gauge steel, enhanced with high-performance PVDF or SMP coatings for unparalleled color durability and UV stability. Aluminum composite panels also provide a lightweight, highly corrosion-resistant cladding solution for high-rise façades, expertly balancing striking aesthetics with robust performance. We deliver the commercial solutions that stand out and stand strong.

Unlocking Project Success with Custom Metal Fabrication Services

Partnering with a specialized metal contractor like Metal Contractors brings unparalleled material expertise, precise fabrication, and installation efficiency directly to your project. Our custom services don’t just meet expectations—they elevate quality and significantly reduce risk, ensuring your vision becomes a flawless reality.

The Unmatched Advantages of Custom Metal Fabrication for Your Project

Custom fabrication ensures that your metal sheets are cut, bent, and finished to exact specifications, minimizing waste and eliminating costly on-site adjustments. Our precision welding and forming techniques deliver consistent seams and tight tolerances, dramatically improving weatherproofing and enhancing the overall aesthetic appeal of your structure. Tailored solutions also expertly address unique design requirements and complex geometries, providing a level of craftsmanship that off-the-shelf options simply cannot match.

How Metal Contractors in Oklahoma City Elevate Material Selection

As local metal contractors, we combine intimate regional climate insights with extensive material knowledge to recommend the absolute ideal gauge, alloy, and finish for your specific needs. We provide tangible sample mock-ups, crucial corrosion testing data, and transparent cost comparisons, helping you perfectly balance performance with your budget. Engaging our fabricators early in your design phase is a smart move—it prevents costly changes later and ensures a seamless, efficient project from start to finish.

Common Custom Fabrication Projects We Bring to Life with Metal Sheets

Our expertise spans a wide range of custom projects, including durable residential metal roofing, distinctive decorative siding panels, sleek commercial storefronts, efficient HVAC ductwork, robust industrial equipment enclosures, and intricate architectural accents. By reviewing our extensive case studies and glowing testimonials, you’ll gain complete confidence in our contractor capabilities and the proven performance of our materials. We turn complex visions into stunning realities.

Your Top Questions About Choosing Metal Sheets, Answered by Experts

We believe in empowering you with knowledge. Answering these key queries helps you make informed decisions and anticipate potential challenges, eliminating guesswork and preventing costly reordering.

What Is the Strongest Type of Sheet Metal for Construction?

For ultimate strength in construction, steel sheet metal, particularly high-strength alloy grades like AHSS (Advanced High-Strength Steel) or stainless steel, offers the highest tensile strength, reaching up to 750 MPa. When you need unparalleled load-bearing capacity and superior impact resistance, low-alloy structural steels are truly unmatched in both commercial and demanding industrial applications. They are built to last.

How Do You Prevent Rust and Corrosion on Metal Sheets?

Preventing rust and corrosion on metal sheets is crucial for longevity. We achieve this by applying advanced protective coatings—such as galvanized zinc, Galvalume, durable powder coats, or high-performance PVDF finishes—which create an impenetrable barrier against moisture and oxygen. Regular maintenance, diligent sealant reapplication at seams, and prompt repair of any scratches are also vital practices that preserve corrosion resistance for decades, ensuring your investment endures.

How Do You Interpret Metal Sheet Finishes and Coatings?

Understanding metal sheet finishes and coatings is key to optimal performance. Finishes like mill (bare), galvanized, Galvalume, and painted coatings each serve specific, vital purposes. Galvanized uses zinc for sacrificial protection; Galvalume adds aluminum for enhanced barrier performance and superior corrosion resistance; and PVDF paints deliver exceptional color retention and UV resistance, crucial for outdoor exposure. Selecting the right finish precisely aligns with your project’s exposure conditions and desired design aesthetics, ensuring both beauty and durability.

How Does Metal Sheet Selection Affect Project Longevity and Maintenance?

Choosing the appropriate alloy, gauge, and finish upfront is the single most effective way to reduce future maintenance cycles and significantly lower long-term costs. Corrosion-resistant materials and durable coatings actively prevent rust and degradation, while proper gauge selection minimizes denting and structural fatigue. Investing wisely in long-term durability directly lowers lifecycle expenses, preserves your property value, and provides lasting peace of mind.

Your Trusted Source: Quality Metal Sheets and Fabrication Services in Oklahoma City

Securing reliable suppliers and expert fabricators is paramount to ensuring your project’s success and a smooth procurement process right here in the OKC area. At Metal Contractors, we are your local solution.

What to Look for in a Local Metal Contractor

When choosing a metal contractor, seek out those with local industry certifications, comprehensive equipment for precise cutting, bending, and welding, and robust portfolios showcasing successfully completed residential and commercial projects. Always verify their service area coverage, the warranty offerings on their work, and their proven on-time delivery performance. At Metal Contractors, we meet and exceed these standards, ensuring your peace of mind.

How Customer Testimonials and Case Studies Demonstrate Our Quality

Real-world examples of our projects—such as a recent Edmond metal roof using 26 gauge Galvalume steel, or a custom commercial siding installation—powerfully showcase our contractor expertise, the superior performance of our materials, and the high level of customer satisfaction we consistently achieve. Positive reviews on durability, aesthetics, and clear communication build undeniable trust in our service quality and commitment to excellence.

Ready to Start? Request a Quote or Consultation for Your Metal Sheet Project Today!

Don’t wait to transform your vision into reality. Contact Metal Contractors online or by phone today to schedule a free, no-obligation material consultation. Provide us with your project details—scope, drawings, desired metal type, and finish—and receive a customized, transparent estimate. Explore our specialized services like Residential Metal Roofing Oklahoma City, Commercial Metal Siding Solutions, or Custom Metal Fabrication Services to begin your project with the confidence that only comes from working with true experts.

Selecting the right metal sheet demands a clear understanding of material properties, gauge implications, environmental challenges, and fabrication capabilities. By expertly assessing steel, aluminum, copper, zinc, and specialty alloys against your project requirements and Oklahoma City’s unique climate, you ensure optimal performance and unparalleled longevity. Leveraging our custom metal fabrication services connects you with local expertise and precise execution, guaranteeing a flawless outcome. When you’re ready to transform your design into reality, request a quote from Metal Contractors—the experienced metal contractors who specialize in superior sheet metal solutions across Oklahoma City. We’re here to build your vision to last.