Maximize Your Footprint: The Definitive Guide to Mezzanine Floor Installation and Design in Oklahoma City

If you own or manage a commercial, industrial, or warehouse space in Oklahoma City, you know the pressure of growth. Your inventory is expanding, your team needs more office space, or your manufacturing line requires a dedicated area. But moving is expensive, time-consuming, and often logistically impossible. So, what’s the smartest, most cost-effective way to find space when you’re already running out of room?

The answer is literally up.

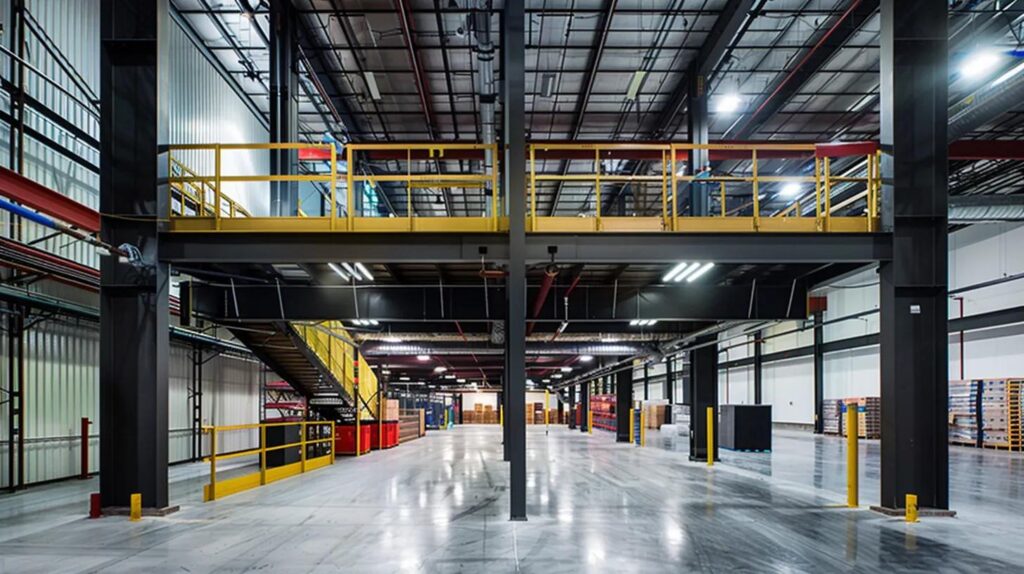

A properly designed and installed structural mezzanine floor is the gold standard solution for maximizing vertical space. It’s not just a temporary platform; it’s a permanent, load-bearing structure engineered to double your usable square footage without the headache of external expansion or the need to buy more land.

As expert mezzanine floor builders and structural steel contractors right here in the heart of OKC, we at Metal Contractors have streamlined the process of integrating high-quality mezzanines into all types of facilities—from bustling downtown distribution centers to local manufacturing facilities. We understand Oklahoma’s climate, codes, and commercial needs.

This definitive guide breaks down everything you need to know, from initial design and structural requirements to code compliance and finding the right mezzanine floor contractors to execute your vision. When you finish reading, you’ll have all the actionable knowledge you need to take your facility to the next level—literally.

Why a Structural Mezzanine Is Your Smartest Expansion Move

In the competitive landscape of Oklahoma business, every square foot counts. A mezzanine floor installation isn’t just a construction project; it’s a strategic business decision that provides immediate, measurable returns on investment. When you compare it to the cost and disruption of breaking ground on a new building, the choice is clear.

Doubling Your Usable Square Footage Immediately

Think about the high ceilings in most commercial metal building contractors near me structures—it’s all wasted potential. A mezzanine taps into that vertical space, creating a new floor level. This new space can be used for a host of high-value functions:

- Storage: A secondary level is perfect for bulk storage, archival records, or staging product before shipment.

- Office Space: Many clients use mezzanines to build enclosed, climate-controlled offices or break rooms, separating administrative tasks from the noisy production floor.

- Manufacturing/Assembly: They can house lighter assembly lines, specialized equipment, or quality control stations, freeing up the primary floor for heavy machinery.

Avoiding Costly Physical Expansion and Relocation

Relocating your operations or undergoing a massive external expansion means dealing with new permitting, extended timelines, and a massive disruption to your workflow. Mezzanine installation, especially when handled by experienced mezzanine installers like Metal Contractors, happens mostly indoors and often takes a fraction of the time. We can usually keep your operations running smoothly, minimizing downtime—which, in the business world, is money saved.

The Financial Advantage and Accelerated Depreciation

From a financial perspective, mezzanines are highly attractive. In many cases, a structural mezzanine floor can be treated as capital equipment or equipment support structure rather than part of the building’s permanent structure. This distinction is critical because it may allow the investment to be depreciated over a much shorter period (often seven years) than a conventional building addition (39 years). Always consult your financial advisor, but the potential for accelerated depreciation makes this a highly cost-effective expansion strategy.

The Structural Blueprint: Red Iron, Steel, and Engineering Precision

A mezzanine is only as strong as the materials and engineering that support it. This is where the choice of structural steel contractors becomes paramount. You are retrofitting a massive load-bearing structure, and there is no room for error.

The Role of Structural Steel Contractors

The entire system relies on a framework of robust structural steel—often referred to as red iron in the industry, due to the rust-inhibiting primer applied to it. This structural integrity is what holds thousands of pounds of inventory, equipment, or personnel.

An expert structural steel contractor handles every step of the process with meticulous precision:

- Load Calculation: Determining the required live and dead load capacities based on your intended use (e.g., storage mezzanines require higher load ratings than office mezzanines).

- Foundation Analysis: Assessing the existing concrete slab and foundational systems to ensure they can bear the new point loads transferred by the mezzanine columns.

- Beam and Column Design: Utilizing high-grade steel beams, columns, and purlins to create a strong, clear-span framework that maximizes open space underneath.

The quality of the steel fabrication is non-negotiable. At Metal Contractors, we utilize state-of-the-art facilities to ensure every column and beam is cut and punched to exact specifications, guaranteeing a flawless fit on-site.

Precision in Metal Fabrication and Custom Design

While many mezzanines use standardized components, true quality and perfect integration come down to custom metal fabrication. For example, fitting a mezzanine into a tightly confined or oddly shaped area often requires custom-cut stringers or unique bracing configurations.

Our in-house metal fabrication shop ensures that all connection plates, bracing, and support elements are manufactured with the highest precision. This capability is essential for creating:

- Custom Crossovers: To integrate the mezzanine with existing equipment or roof-level access.

- Specialized Columns: Designed to circumvent existing ductwork or machinery on the ground floor.

- Architectural Metalwork: Including custom staircase risers and decorative fascia that may be required for public-facing areas of the mezzanine.

This blend of structural engineering know-how and specialized fabrication is what distinguishes a reliable metal construction company from an average contractor.

System Selection: Freestanding vs. Building-Supported

Mezzanines generally fall into two categories, and the right mezzanine floor contractors will recommend the correct type based on your facility and future growth plans:

- Freestanding (Structural): These are independent structures supported by their own columns and foundations. They are often preferred because they are fully demountable, portable, and do not rely on the structural integrity of the existing building walls. This offers maximum flexibility and is easier for permitting.

- Building-Supported (Deck-Supported): These systems utilize the existing building columns or walls for partial support. While potentially using less material, they are less flexible and require highly specialized structural analysis to ensure the existing building can handle the new loads.

For flexibility, the freestanding structural steel approach is often the superior long-term investment for OKC businesses.

Beyond the Floor: Essential Metal Construction and Safety Requirements

A mezzanine isn’t complete until it’s safe, accessible, and compliant with all local standards. This requires incorporating other essential metal construction services and components.

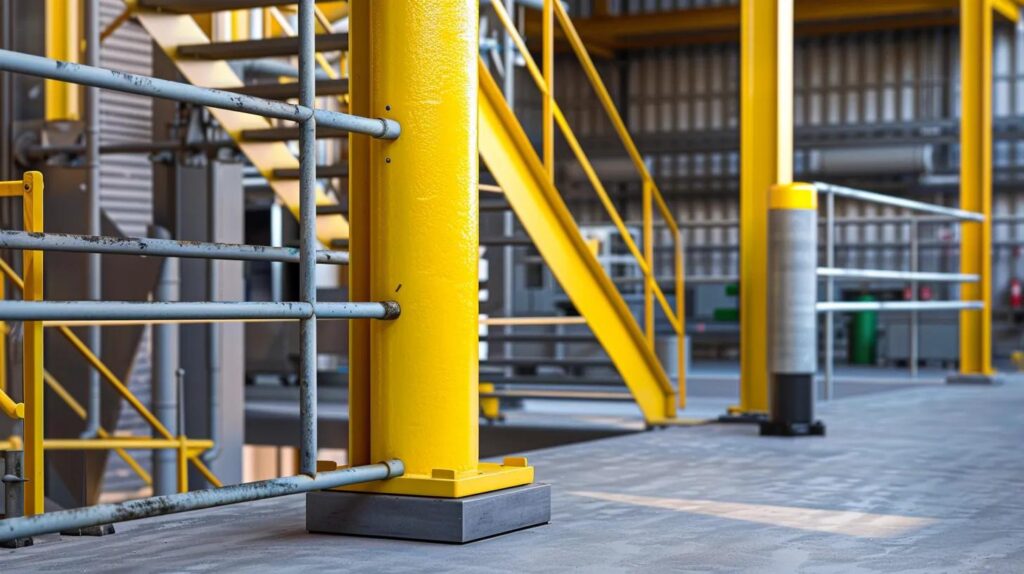

Safety Railing and Access Ladder Requirements

Safety is the absolute priority. Every mezzanine requires robust safety railing, usually 42 inches high, with a mid-rail and kick plate (toe board). As specialized railing installation companies near me know, this railing must be constructed from durable steel and securely bolted or welded to the floor deck.

Access is typically provided via industrial access ladders or structural steel stairways. A certified contractor will ensure that all stairs meet IBC (International Building Code) and OSHA regulations for commercial access, including proper rise, run, and tread construction. For high-traffic areas, structural steel stairs are mandatory, not optional, and must be designed and installed by expert hand rail installers near me.

Ground-Level Protection: Bollard Construction

Once the mezzanine is installed, the columns supporting it—especially in a busy warehouse or factory—become vulnerable to forklifts, vehicles, or heavy equipment. This is where professional bollard construction and installation is critical for safety and structural protection.

- What are bollards in construction? They are robust, vertical posts (typically steel pipe filled with concrete) installed into the ground to provide a physical barrier against vehicle impact.

- The Importance of Bollard Installation Contractors: Properly installed bollards protect your mezzanine’s structural support columns from lateral impact damage. This not only prevents catastrophic structural failure but also shields the significant investment you made in the new floor. A professional will correctly determine the required depth, diameter, and distance from the column to absorb impact effectively.

Integrating Mobile Welding and Custom Features

During installation, there may be unexpected field modifications or the need for tie-ins to existing structural steelwork contractors systems. Having a team that offers on site welding services and operates a highly professional mobile welding shop is invaluable. Whether it’s securing a handrail or modifying a custom bracket, mobile welding and fabrication capability on-site speeds up the project and eliminates costly delays associated with transporting materials back to a shop.

This capability also extends to adjacent services like the installation of awning contractors or canopy construction that might be attached to the existing metal building exterior—often requested by clients who are modernizing their entire facility.

FAQs About Structural Steel & Mezzanine Construction

Clients often have specific questions about the longevity and logistics of these complex structures.

Q: Is structural steel construction safe in Oklahoma’s severe weather? A: Yes, absolutely. Steel is known for its superior strength-to-weight ratio and elasticity, making it highly resilient to high winds and seismic activity common in Oklahoma. A building or mezzanine framework constructed using high-grade red iron and proper engineering standards will far outlast structures made of traditional materials and is designed to meet or exceed Oklahoma’s strict building codes.

Q: How long does it take for a mezzanine floor contractors team to complete an installation? A: The duration depends heavily on the size and complexity. A small, standardized mezzanine (around 1,000 sq ft) might take 2-3 weeks, but larger, complex structural mezzanines requiring custom metal fabrication, heavy structural steel erection, and extensive railing installation could take 4-8 weeks from start to finish. The majority of the structural frame goes up quickly; the time is often spent on decking, safety features, and final fit-out (like lighting and office finishes).

Q: Can you install a mezzanine in an existing building with low ceilings? A: There are specific minimum clearance requirements mandated by OSHA and local codes (usually around 7 feet of clearance both above and below the mezzanine). While we are expert metal contractors who specialize in maximizing space, if your current ceilings are too low, a mezzanine might not be feasible. We conduct a thorough site assessment during the initial phase to ensure code compliance and optimal design.

Q: What is the difference between custom metal and fabrication and pre-engineered components? A: Custom metal fabrication is the process of creating unique, bespoke steel parts—like decorative architectural metal, unique access ladders, or specialty machinery bases—designed specifically for your project. Pre-engineered components are standardized, modular parts that assemble quickly. The best metal construction company offers both, combining the speed and cost-effectiveness of pre-engineered systems with the precision of custom fabrication where it truly matters.

Q: What’s the primary function of bollards in construction, and how are they installed? A: The main function of a bollard in construction is physical protection. They act as sacrificial barriers to stop vehicles, forklifts, or machinery from hitting critical assets. Professional bollard installation contractors core-drill into the concrete slab, set the steel pipe, and then fill it with concrete and often finish it with a protective cap or sleeve. This makes them incredibly durable.

FAQs About Metal Contractors

As Oklahoma City’s leading metal construction company, we believe in total transparency. Here are answers to common questions about how we operate.

Q: Where does Metal Contractors provide its services? A: Our primary service area is Oklahoma City and the surrounding metro areas, including Norman, Edmond, Moore, and locations within a 50-mile radius. We are dedicated to supporting the growth of local Oklahoma businesses with our expertise in structural steel, mezzanines, awning companies okc, and mobile welding service near me. We know the local regulatory landscape better than anyone.

Q: Does Metal Contractors handle the entire mezzanine project, including design and permitting? A: Yes. We are a comprehensive, full-service metal construction company. We utilize a Design-Build approach, meaning we handle everything from initial structural engineering and load calculations to precision custom metal fabrication in our local shop, and final on-site installation and permitting documentation. We simplify the entire process for you.

Q: Do you offer mobile welding and emergency repair services? A: Yes. We operate a fully equipped mobile welding company that provides expert, certified onsite welding services for repairs, emergency structural fixes, and quick modifications. Our welders in okc are highly certified to handle everything from light fabrication to heavy structural fixes, ensuring your downtime is minimized.

Q: How does Metal Contractors ensure quality and safety on structural steel projects? A: Quality and safety are our highest priorities, and we adhere to strict principles. Our team includes AWS (American Welding Society) certified welders in oklahoma city, we adhere to AISC (American Institute of Steel Construction) standards for all structural steel work, and maintain a low Experience Modification Rate (EMR) as a testament to our impeccable safety record. We are fully licensed, bonded, and insured steel contractors.

Q: Beyond mezzanines and structural steel, what other commercial services do you offer? A: We are comprehensive metal construction company experts. Our services include:

- Full-service metal fabrication custom for architectural elements.

- Design and installation of commercial canopy contractors and awning contractors.

- Installation of industrial safety railings, access ladders, and fencing.

- Bollard installation contractors for asset and facility protection.

- Heavy structural fixes and metal building repair contractors near me services.

Meet the Experts: About Metal Contractors

In the construction world, trust is built on experience, authority, and accountability. At Metal Contractors, we have forged a reputation as the leading steel contractors and metal construction company in the Oklahoma City metro area by upholding the highest standards of Expertise, Experience, Authority, and Trust.

Our History and Focus: Founded over a decade ago right here in OKC, Metal Contractors was built on the principle of delivering superior metalwork that stands up to Oklahoma’s unique demands. We saw a need for a structural steel firm that didn’t just install pre-fab parts but offered true, precision customized metal fabrication and comprehensive structural engineering. Our focus is squarely on high-stakes commercial and industrial projects where quality and code compliance are non-negotiable.

Our Authority and Certifications: Our team is comprised of professional engineers, master fabricators, and dedicated project managers. Every one of our field welders in oklahoma city holds advanced certifications from the American Welding Society (AWS). We strictly follow the latest building codes, including IBC and local Oklahoma City/County regulations, ensuring every piece of red iron and structural component we install is engineered for maximum safety and longevity. Our robust insurance policies and low EMR are public evidence of our commitment to safety and professional conduct.

Our Expertise in Action: From complex structural steelwork contractors projects involving multi-story building frames to specialized, custom jobs like unique awnings oklahoma city installations or intricate mezzanine floor contractors fittings, our portfolio is diverse. We pride ourselves on the fact that when other contractors call for complex metal solutions, they call Metal Contractors. Our state-of-the-art metal fabrication shop utilizes CNC plasma cutters and advanced welding stations, giving us control over the quality of every component from blueprint to final bolt-up. We don’t just build structures; we build relationships founded on proven excellence.

Your Next Step to Maximizing Space and Value

The need for more space in your commercial facility is a sign of success, and solving that problem shouldn’t involve disruption, excessive cost, or compromise on quality. A structural mezzanine, built by expert mezzanine floor builders using certified structural steel and high-precision custom metal fabrication, is the most efficient and valuable solution available to commercial metal building contractors near me and business owners alike.

At Metal Contractors, we combine our deep local knowledge of the Oklahoma City market, our state-of-the-art metal fabrication shops to deliver a seamless, high-quality solution. Whether you need a simple storage mezzanine, complex hand rail installers near me services, or robust ground-level bollard construction, we are your trusted partner.

Ready to see how much untapped potential your facility holds? Contact Metal Contractors today for a detailed consultation and take the first step toward doubling your usable footprint.