The Oklahoma City Blueprint: Navigating Structural Steel, Custom Fabrication, and Mobile Welding Services

If you’re launching a major construction project in the Oklahoma City metro area, you know that the foundation of success isn’t just concrete—it’s metal construction. From the towering structural steel frames that define our skylines to the bespoke, architectural metalwork that gives a building its character, choosing the right partner is the single most critical decision you’ll make.

This isn’t just about finding a welding mobile services provider; it’s about partnering with a full-spectrum metal construction company that brings precision, expertise, and local knowledge to every stage. Here in Oklahoma, where the weather demands durability and the business environment prizes efficiency, your metal components need to be robust, perfectly engineered, and installed by certified professionals.

Many contractors offer a limited service set, forcing you to juggle multiple vendors—one for the structural steel contractor work, another for sheet metal fabrication, and a third for an urgent on-site welding service near me. That complexity adds cost and risk.

This guide is designed to cut through that complexity. We’ll show you the three main pillars of modern metal construction in OKC—structural steel, custom fabrication, and mobile services—and explain how a single, expert firm like Metal Contractors can seamlessly integrate them into your project.

Whether you’re a general contractor breaking ground on a new commercial complex, a business owner needing metal building repair contractors, or a homeowner looking for a perfect custom railing, understanding these fundamentals is your first step toward building a successful, lasting structure.

Forget the endless searching for “welders in okc” or “metal fabrication shop near me.” Let’s look at the blueprint for quality.

Decoding Structural Steel: The Backbone of OKC's Modern Buildings

When you look at Oklahoma City’s rapidly growing commercial landscape—the new office buildings, retail centers, and industrial facilities—you are primarily looking at the strength of structural steel.

This material is the undisputed champion for large-scale, load-bearing construction, prized for its strength-to-weight ratio, resilience, and speed of erection. A high-quality structural steel frame ensures your building can withstand everything from heavy snow loads to high winds, offering unmatched safety and longevity.

Working with structural steel contractors is a precise science, not guesswork. It involves complex calculations and adherence to national standards to ensure every column, beam, and truss performs exactly as engineered. This is why you need a partner who views structural integrity not as a goal, but as a given.

AISC Standards: What They Mean for Your Project

Any reputable structural steelwork contractors in the OKC area must operate under the guidelines set by the American Institute of Steel Construction (AISC). This certification is the gold standard, signifying that a fabricator and erector adheres to rigorous quality management systems, has certified welders oklahoma city on staff, and follows strict codes for everything from material sourcing to final bolt-up.

For the client, working with an AISC-compliant contractor means:

- Verified Materials: You are guaranteed that the steel used is the correct grade and quality for the intended application.

- Precision Fabrication: Components are created with tight tolerances, meaning they fit together perfectly on-site without costly delays or modifications.

- Certified Safety: The contractor follows industry best practices for safety during the crucial erection phase, minimizing risk for personnel and property.

The detailing process—where shop drawings are created from the engineer’s blueprint—is equally crucial. Utilizing modern technology like 3D modeling and BIM (Building Information Modeling) allows experienced firms to spot potential conflicts long before the steel arrives on the job site. This is where real-world cost savings are found, transforming the detailing phase from a necessary step into a strategic asset.

If your project requires multi-story or large-span commercial construction shelter or industrial facilities, the choice of structural steel contractor is literally the foundation of your success. Settling for anything less than certified expertise is a risk no builder can afford to take. The material itself is an investment in the future resilience and value of your commercial property.

Mobile Welding vs. Shop Fabrication: A Decision Guide for Contractors

The world of welding is often split into two distinct, yet complementary, services: mobile and shop-based. Understanding the specialized application of each service is key to optimizing your project timeline and budget. For a leading metal construction company, proficiency in both is non-negotiable, offering clients the flexibility to tackle any challenge.

When is On-Site Welding a Must?

When searching for “mobile welding service near me,” you are typically looking for immediate, flexible, and powerful solutions that eliminate the logistical nightmare of moving large, immovable objects. Mobile welding and fabrication services are dispatched directly to your location, equipped to handle everything from emergency repairs to final installations.

Here are the scenarios where on-site welding services shine:

- Emergency Repairs: Equipment breakdown, unexpected structural damage, or a last-minute modification can halt a project. A mobile welding company offers rapid response to get things back on track, minimizing costly downtime.

- Structural Tie-Ins: Connecting prefabricated steel components, such as tying in a new addition to an existing frame, requires specialized on-site certification and equipment. Structural steel contractor services often rely on mobile welders for these critical connections.

- Large-Scale Installations: Elements like stair railing systems, industrial piping, and large canopy construction frames often arrive in segments. They must be assembled and permanently affixed at the final location, a job perfectly suited for a mobile welding shop.

- Custom Security and Railing: Services like railing installation companies near me often use mobile units to perform final measurements, custom cuts, and welding of hand rails or fencing directly at the property, ensuring a seamless and secure fit.

The convenience of a portable welding company is invaluable, but they must maintain the same standard of certification as a shop. Always ensure the mobile welding company you choose employs certified, experienced welders in okc who understand the unique challenges of outdoor and on-site conditions.

The Precision of Dedicated Shop Fabrication

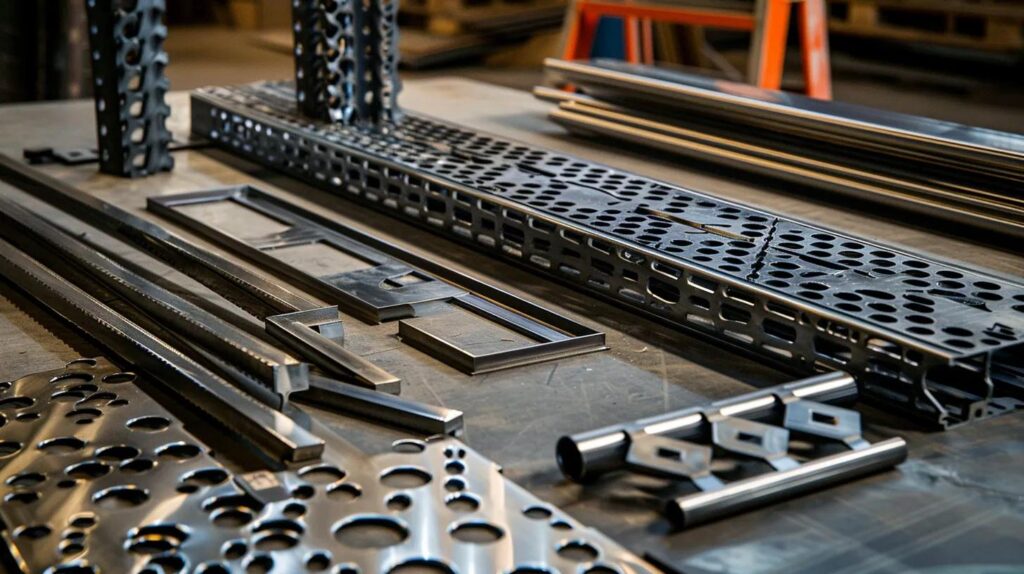

In contrast, dedicated shop fabrication—like that offered by a premium metal fabrication shop—is all about precision, scale, and environmental control. This is where specialized, non-portable machinery comes into play: plasma cutters, press brakes, sheet metal rollers, and high-capacity welding jigs.

- Custom Parts: Creating components with tight tolerances, such as specialized brackets, precision sheet metal fabrication pieces, or intricate decorative metalwork, requires the controlled atmosphere of a shop.

- Volume Production: If your project requires dozens of identical custom metal and fabrication parts, the efficiency and consistency of a shop are unmatched.

- Complex Assemblies: Shop fabrication allows for the assembly of large, complex units—like entire mezzanine floor contractors sections or detailed custom shelters—before they are transported to the site for final erection, saving significant time on the construction schedule.

For clients requiring services like custom sheet metal fabrication or mezzanine floor builders, the decision is clear: shop fabrication ensures the highest level of quality control and precision, setting up the on-site welding team for a smooth installation.

The Art of Custom Metal Fabrication

Metal construction goes far beyond standard structural beams; it encompasses the art and science of custom fabrication metal. This is where a client’s unique vision meets the engineer’s practical requirements, resulting in functional, aesthetic, and durable elements. Oklahoma City businesses often require specialized pieces that simply don’t exist off the shelf—from custom machine guards to architectural features that define a brand identity.

Sheet Metal vs. Structural Fabrication: Knowing the Difference

While both fall under the umbrella of metal fabrication shop, these two types of fabrication serve vastly different purposes:

- Structural Fabrication: Deals with materials and components that bear the load of a building or structure. This involves heavy W-sections, channel steel, and thick plates. Services include building structural steel contractor members, industrial canopy contractors frames, and hand rail installers near me that require load-bearing strength.

- Sheet Metal Fabrication: Involves working with thinner, lighter-gauge metals (like those used for HVAC, cladding, or decorative purposes). This process is highly focused on bending, shearing, laser cutting, and forming (sometimes referred to as fabrication sheet metal or metal fabrication sheet metal) to create precise enclosures, ductwork, and architectural panels. The specialized equipment in a metal fabrication shop near me for sheet metal allows for the extreme accuracy needed in these applications.

A full-service metal fabrication shop is equipped to handle both, meaning your project’s intricate customized metal fabrication needs—whether it’s a delicate architectural facade or a robust awning construction support—can be met by a single team.

Materials Matter: Working with Aluminum, Stainless Steel, and Carbon Steel

The type of metal chosen dictates the performance and longevity of the fabricated component. Expert metal contractors are fluent in the properties of each:

- Carbon Steel (Mild Steel): The workhorse of construction. Excellent for general structural applications, highly weldable, and cost-effective. Requires protective coatings (like paint or galvanization) to prevent rust. Used extensively for structural steel contractor work, mezannine floor contractors, and general metal construction company projects.

- Aluminum: Lightweight, naturally corrosion-resistant, and aesthetically pleasing. Ideal for awning contractors and canopy construction where weight is a factor, or for decorative elements that require long-term exterior exposure without rust.

- Stainless Steel: The premium choice for hygiene, extreme environments, and architectural longevity. It is highly resistant to corrosion and does not require painting. While more expensive, it is often chosen for high-end custom metal fabrication for restaurants, medical facilities, and exterior railing installation companies near me where low maintenance is critical.

A reliable contractor should be able to offer welding certifications (TIG, MIG, and Stick) across all these materials, ensuring that every weld—from a decorative aluminum railing to a load-bearing stainless steel support—is executed to the highest quality standard. This material fluency is a hallmark of truly professional fabrication custom metal services.

Beyond Walls: Enhancing Safety and Functionality with Architectural Metalwork

The most visible and frequently used elements of a structure are often the specialty metal installations: the railings, canopies, and security barriers. These features, handled by contractors metal works, are crucial for both user experience and property protection.

Commercial Awnings and Canopies: A Shelter Solution

For commercial properties in Oklahoma City, where sun and rain can be intense, an investment in a durable awning or canopy offers immediate returns in comfort and energy savings.

- Awnings: Typically attached to the building facade, often used above doors and windows. Metal-framed awnings by expert awning contractors provide strong support for various fabric or metal sheeting.

- Canopies: Freestanding or semi-freestanding structures designed to cover large areas, such as walkways, loading docks, or carports. Canopy contractors build these using robust structural steel or aluminum frames.

The key here is installation quality. Awning companies okc must understand local wind load requirements. A structural steel canopy, for instance, requires a deep, properly engineered foundation to prevent uplift and ensure safety, a core competency of any reputable steel contractors.

Bollard Installation: Essential Security and Traffic Control

Often overlooked until an incident occurs, bollards are simple yet highly effective metal posts designed to protect buildings, utilities, and pedestrians from vehicle impact.

Different Types of Bollards in Construction

When discussing “what are bollards in construction,” we refer to several types installed by bollard installation contractors:

- Security/Crash-Rated Bollards: Designed to stop vehicles traveling at specific speeds. These are common outside high-security buildings and storefronts. They are typically set deep into concrete footings and filled with rebar and concrete.

- Architectural/Decorative Bollards: Used to define perimeters, enhance aesthetics, and guide traffic. While not crash-rated, they provide a visual and physical deterrent.

- Removable Bollards: Allow for temporary vehicle access to restricted areas.

Understanding the correct placement of bollards in construction is critical. A qualified bollard construction or bollard installation contractors service ensures that these safety features are installed to precise specifications, turning simple metal posts into powerful, passive security barriers. This level of detail elevates a project from functional to secure.

Why Local Expertise Matters: Choosing OKC Metal Contractors

In an industry built on trust and reliability, choosing local contractors metal works like Metal Contractors provides an irreplaceable advantage, especially in a dynamic market like Oklahoma City.

Local presence means:

- Rapid Mobilization: For urgent jobs, especially those requiring mobile welding service near me, a local firm can dispatch a certified team faster than an out-of-town competitor. This minimizes critical downtime for commercial operations.

- Understanding Local Codes: From specific wind load requirements for awning construction to fire codes for a mezzanine floor builders project, local steel structure contractors are intimately familiar with OKC and Oklahoma state building regulations. This expertise prevents costly reworks and delays during inspection.

- Community Reputation: A local metal construction company relies on word-of-mouth and a consistent track record of excellence. Their long-term commitment to the area translates into an unwavering commitment to quality on every job, whether it’s a residential fence or a complex structural steel contractor build.

When vetting potential partners, look for proof of their local work—photographs of custom metal fabrication projects, testimonials from OKC-based clients, and a dedicated team of welders oklahoma city. Your partnership should be built on trust, demonstrated competence, and a shared commitment to building something lasting in Oklahoma.

FAQs About Structural Steel

This section focuses on answering key questions related to the high-volume topic of “structural steel” and its related long-tail queries.

Q: What is the main difference between structural steel and pre-engineered metal buildings (PEMBs)?

A: Structural steel frames are custom-designed, fabricated, and erected on-site to meet unique architectural and load specifications, often used for large, complex commercial or multi-story buildings. PEMBs use standardized, pre-cut components (beams, columns, sheeting) that are designed for quick assembly and are typically best suited for simpler, large-span, single-story industrial or warehouse structures. While both are built by metal building contractors near me, structural steel offers far greater design flexibility and strength for specialized projects.

Q: Are certified welders required for all structural steel connections?

A: Absolutely. For load-bearing elements in structural steel, all welding must be performed by welders who hold current certification (usually American Welding Society or AWS standards) relevant to the specific welding process and material. Utilizing non-certified or subpar welding companies in oklahoma city on a structural project can compromise the entire structure’s integrity and violate building codes, leading to mandatory and expensive remediation.

Q: What is “Red Iron” and is it the same as structural steel?

A: “Red iron” is a common, informal term used in construction to describe the standard carbon steel members (beams, columns, etc.) that are often coated with a reddish-brown iron oxide primer for temporary rust prevention during transport and erection. Yes, red iron is generally considered standard structural steel, often used by redd iron contractors, and is the base material for many steel structure contractors projects.

Q: How long does it take for a structural steel frame to be erected?

A: The timeline varies significantly based on the project’s size and complexity. However, a major advantage of structural steel is the speed of installation compared to concrete. Since the pieces are prefabricated in the metal fabrication shop and simply bolted/welded together on-site, a standard commercial frame can often be erected in weeks rather than months, provided the structural steelwork contractors have done proper planning and detailing.

Q: Can I use structural steel for a commercial metal building repair?

A: Yes, structural steel is ideal for repairs, especially where an existing structure needs reinforcement or modification (like adding a mezzanine floor contractors installation or strengthening a roof for new equipment). Metal building repair contractors will often use structural steel to splice, reinforce, or replace damaged load-bearing members, ensuring the repaired section is stronger than the original.

FAQs About Metal Contractors

This section helps establish the Experience, Expertise, Authoritativeness, Trustworthiness of the client, Metal Contractors.

Q: What types of projects does Metal Contractors specialize in?

A: Metal Contractors specializes in a comprehensive range of metal construction services for both commercial and residential clients in the OKC metro area. Our core specializations include certified structural steel fabrication and erection, mobile and on-site welding services, and high-precision custom metal fabrication for architectural and functional needs. This includes installing canopy contractors structures, bollard construction, custom awning contractors systems, and specialized safety features like access ladders and railings.

Q: Do you offer residential services, or are you strictly commercial?

A: While we are recognized as leading commercial metal building contractors near me for industrial and commercial projects, we proudly serve residential clients as well. We handle custom railing installation companies near me projects, decorative gates, custom metal fencing, and specialized structural repairs, treating every project—regardless of size—with the same commitment to precision and quality that defines our commercial work.

Q: What area do Metal Contractors cover for mobile welding?

A: We serve Oklahoma City and the surrounding areas within a 50-mile radius, including Norman, Edmond, Moore, and Mustang. Our welding mobile services are designed to provide rapid, convenient, and certified on-site support right to your job site or business, minimizing downtime and logistical hurdles. If you need a certified mobile welding service near me, we can reach you quickly with fully equipped service trucks.

Q: How does Metal Contractors ensure the quality of their custom fabrication?

A: Quality is ensured through three key phases: 1) Design and Detailing: We utilize advanced CAD and detailing software to create precise shop drawings before any metal is cut. 2) Material Selection: We use only verified, high-grade materials (steel, stainless steel, aluminum). 3) Certified Workmanship: All fabrication and welding is performed in our metal fabrication shop by AWS-certified welders who adhere to strict quality control protocols throughout the custom fabrication metal process.

Q: Are your welding services certified for structural work?

A: Yes. Our welding contractors and welders in okc hold multiple certifications, including those required for structural steel (AWS/AISC standards). Whether we are performing work in our shop or delivering on-site welding services, our certifications ensure that every weld meets or exceeds industry requirements for strength and integrity.

About Us: Metal Contractors – Building Oklahoma’s Future

Metal Contractors is a cornerstone of the Oklahoma City construction scene, driven by a philosophy centered on Experience, Expertise, Authority, and Trustworthiness.

Our Credentials:

- Experience: Founded by a team of veteran metal contractors with decades of combined experience in the regional structural steel and mobile fabrication industry. We understand the unique environmental and regulatory challenges of building in Oklahoma.

- Expertise: Our team comprises certified professional engineers (PEs), accredited detailers, and AWS-certified welders oklahoma city. This technical expertise allows us to seamlessly transition between complex structural builds, delicate sheet metal fabrication projects, and precision custom shelters.

- Authority: We have been the trusted partner for some of the OKC metro area’s most challenging and iconic commercial developments, specializing in projects that demand the highest level of structural integrity and custom design. We are not just fabricators; we are solution providers and structural steelwork contractors who consult with clients from concept to completion.

- Trustworthiness: We operate on principles of transparency and reliability. Every estimate is detailed, every project timeline is realistic, and every material is verifiable. Our long-standing relationships with the general contracting community in Oklahoma County attest to our commitment to ethical and high-quality service. We are fully insured, licensed, and dedicated to upholding the highest safety standards on every job site, ensuring peace of mind for our partners.

Your Project Deserves Uncompromising Quality

The success of your next construction project—from a durable commercial metal building contractors near me structure to a secure bollard-protected entry—hinges on the quality of its metalwork.

By choosing a partner like Metal Contractors who seamlessly combines expertise in certified structural steel contractor services, advanced custom metal fabrication, and responsive mobile welding company capabilities, you are investing in a future of durability, precision, and efficiency.

Don’t settle for scattered vendors; select the full-service metal construction company that provides the complete Oklahoma City Blueprint for success. Get in touch today to discuss how we can turn your toughest designs into reality.