The Definitive Oklahoma City Guide: 10 Questions to Ask Your Structural Steel Contractor

If you’re driving through Oklahoma City today, you can feel the pulse of expansion and growth. From new commercial developments on the south side to renovated industrial parks dotting the 405 corridor, the skyline is constantly evolving. And at the heart of this building boom? Steel. Strong, durable, and versatile, structural steel is the backbone of modern Oklahoma architecture and industrial infrastructure.

Whether you’re planning a massive commercial warehouse, a custom metal fabrication project, or just a new awning for your business, choosing the right structural steel contractor is the most critical decision you’ll make.

This isn’t a choice you should make lightly; your partner needs to understand not just steel, but also the specific demands of building in the OKC area. A great metal construction company brings efficiency, safety, and certified expertise. A poor choice can lead to delays, budget overruns, and compromised structural integrity.

We’ve compiled the 10 most essential questions you need to ask before hiring any contractor. Use this guide to separate the true Oklahoma City experts from the rest, ensuring your next project is built for success, durability, and compliance.

Why Vetting Your Structural Steel Contractor is Mission-Critical

The integrity of your building—be it a massive commercial facility or a customized retail space—hinges entirely on the quality of its structural steel. This material is designed to bear the load, withstand Oklahoma’s often unpredictable weather (hello, high winds!), and provide long-term resilience. Therefore, your vetting process must be rigorous.

When searching for steel contractors and fabrication partners in the Oklahoma City and surrounding areas (within a 50-mile radius, which includes places like Norman, Edmond, and Shawnee), you’re not just looking for a company that can weld two pieces of metal together.

You’re looking for a partner with proven project management, adherence to strict industry codes, and the logistical agility to handle everything from detailed shop drawings to safe, timely installation. This due diligence protects your investment and ensures compliance with local building codes, saving you tremendous time and cost in the long run.

A metal construction company that provides transparent answers to these questions demonstrates experience, competence, and reliability—the three pillars of a successful construction partnership. Make sure the contractor you choose considers themselves a true extension of your team, ready to tackle challenges like material cost fluctuations and complex onsite adjustments with professionalism and expertise.

The Definitive 10 Questions for Hiring an OKC Metal Expert

Navigating the nuances of metal construction requires asking pointed, specific questions. Here are the 10 essential inquiries that will help you assess a potential contractor’s ability to deliver a high-quality, long-lasting project.

Question 1: How Deep Is Your Experience with Projects Like Mine?

Experience is measured not just in years, but in similarity of completed work. A contractor specializing in small railings may not have the infrastructure for a multi-story structural steel frame.

Focus on Scale and Specialization

Ask to see case studies or project examples that directly mirror the scope, complexity, and industry of your proposed construction. If you need a large commercial building, ask to see their work with other commercial metal building contractors near me. If you need intricate, custom work, verify their track record in complex custom metal fabrication. A proven history with similar projects minimizes risk and demonstrates familiarity with your specific challenges.

Question 2: Do You Use In-House Production or Rely on Outsourcing?

A contractor who manages the entire fabrication process—from detailing and cutting to welding and finishing (like painting or blasting)—in their own facility offers a superior guarantee of quality.

The In-House Advantage

When a metal fabrication shop near me handles everything in-house, they maintain complete control over the timeline, material handling, and quality control checks. Outsourcing often introduces communication delays, quality inconsistencies, and unforeseen costs. Look for a partner with a full-service metal fabrication shop and the capability to produce shop drawings and finished components internally. This seamless process is the hallmark of a top-tier metal contractor.

Question 3: What Are Your Onsite Welding and Mobile Service Capabilities?

Construction projects—especially large-scale ones—invariably require immediate adjustments, repairs, or additions on the job site. The ability to perform high-quality field work is non-negotiable for project efficiency.

Finding a Reliable Mobile Welding Company

The presence of a dedicated mobile welding service near me is a game-changer. Ask:

- What equipment do your mobile welding trucks carry?

- Can they handle heavy-duty structural steel repairs on-site?

- Are they available for emergency welding services that minimize costly downtime?

A professional mobile welding company provides the flexibility to address unforeseen issues quickly, preventing minor hiccups from turning into multi-day delays. Onsite welding services ensure quick, precision fitting of structural components, which is critical for staying on schedule.

Question 4: How Do You Guarantee Welding Quality and Certification Compliance?

This is arguably the most crucial technical question. Welding integrity dictates the longevity and safety of the entire structure.

Certification is Non-Negotiable: The AWS D1.1 Standard

The gold standard for structural welding is the American Welding Society (AWS) D1.1 Structural Welding Code for Steel. Your welders in okc and the welding contractors they employ must be able to provide documented proof that their welders and their procedures are current and compliant with this code.

- Welder Qualifications: Request their Welder Qualification Records.

- WPS System: Do they utilize a system for managing Welding Procedure Specifications (WPS)? A well-documented WPS ensures consistency across all welds, detailing variables like material type, preheat temperature, and consumables.

- Quality Manager: Does a dedicated Quality Assurance (QA) manager oversee and inspect all welding performance and fit-ups?

Ensuring they meet these technical benchmarks (like AWS D1.1 certification) confirms their commitment to the highest quality and safety standards.

Question 5: What is Your Shop’s Capacity, Equipment, and Technology?

A fabricator’s equipment directly correlates to their efficiency, precision, and ability to handle complex projects. Outdated tools lead to slower turnaround times and higher costs.

Advanced Tools for Custom Fabrication

Look for advanced tools that increase precision and efficiency, such as:

- CNC Plasma or Laser Cutters

- Automated Beamline Machines (for drilling and cutting structural beams)

- High-capacity press brakes for forming heavy plate.

The capacity of their facility—how many concurrent large-scale projects they can handle without delay—is also a key indicator of reliability. If you need specialized work like a custom mezzanine floor builders project, verify they have the heavy-duty equipment and specialized jigs needed to fabricate those large assemblies accurately.

Question 6: Who Handles Detailing and Shop Drawings?

The translation of architectural plans into real-world steel components requires specialized skill known as detailing.

Detailers Convert Concept to Reality

A top-tier contractor employs in-house detailers who use sophisticated computer-aided design (CAD) software. These detailers are responsible for creating precise shop drawings that the fabrication team uses to cut, shape, and assemble the steel. Accurate detailing eliminates costly errors and ensures that components fit perfectly when they arrive at your job site. Ask for examples of their shop drawings—they should be clear, concise, and incredibly detailed.

Question 7: What Is Your Standard Process for Client Communication?

Poor communication is the number one cause of construction project failure. You need an established, transparent process for updates and issue resolution.

Transparency and Accessibility

Ask who your primary point of contact will be (Project Manager), what the expected response time is, and how they communicate milestone achievements or unexpected issues. The process should be detailed and realistic, accounting for communication buffers and required approval windows. Look for a metal construction company that values open dialogue and keeps you informed every step of the way, ensuring transparency from fabrication to final installation.

Question 8: How Seriously Do You Take Safety, and What Is Your Safety Record?

Safety on the job site protects both the workers and your project timeline. A serious commitment to safety reflects a high level of operational professionalism.

OSHA Compliance and Comprehensive Programs

Your contractor should meet or exceed all current OSHA (Occupational Safety and Health Administration) requirements. Ask:

- Do you have a comprehensive, documented safety program?

- What is your company’s safety record (e.g., the number of lost-time incidents)?

- When was your last OSHA inspection?

Safety standards are part of the quality assurance process (referencing back to welding QC). A safe worksite is an efficient worksite.

Question 9: Do You Have Proven Expertise in Niche Metal Services?

While structural steel may be the foundation, your project likely includes specialized metal features that require niche expertise.

Specialists in Architectural Metal and Commercial Features

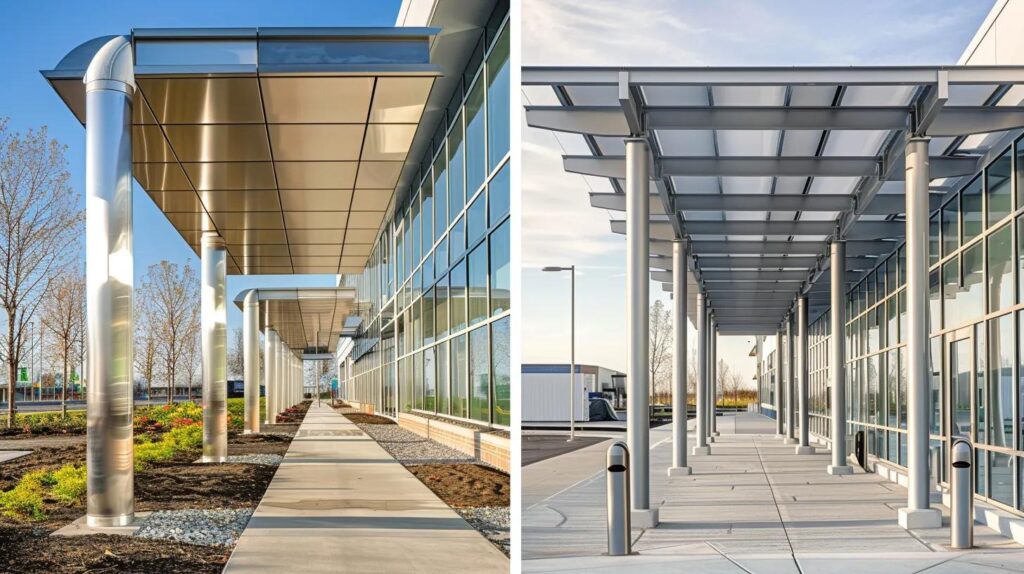

If your project involves commercial aesthetic elements or safety features, ask for specific examples of their work as awning contractors, canopy contractors, or bollard installation contractors. For instance:

- Awnings and Canopies: Can they handle the full scope of awning construction, including design, fabrication, and installation of weather-resistant, architectural metal pieces?

- Mezzanines and Platforms: Do they have experience as mezzanine floor contractors who understand load-bearing requirements and code compliance for platforms?

- Bollards: When it comes to vehicle barriers, verify their expertise in bollards in construction for proper installation and structural integration.

Choosing a contractor who can handle both the heavy structural work (steel framing) and the specialized finishes (like custom shelters or railings) streamlines the project and eliminates the need for multiple subcontractors.

Question 10: What Warranty and Post-Installation Support Do You Provide?

A reputable contractor stands behind their work long after the final bolt is tightened.

Commitment to Longevity

Ask about the typical warranty period for their fabrication and installation services. A confident steel contractor will offer a substantial warranty, typically covering fabrication defects and installation issues for several years. Furthermore, inquire about their availability for future maintenance or repair work, such as steel building repair contractors services, ensuring they can be your long-term partner for the life of your structure.

Spotlight on Niche Services: Bollards and Custom Fabrication

While large-scale structural steelwork contractors often focus on framing, a full-service metal construction company like Metal Contractors seamlessly integrates highly specialized features that enhance both the function and aesthetic of your property.

For example, safety and security are paramount in any Oklahoma City commercial space. This is where bollards construction comes into play. What are bollards in construction? They are sturdy, vertical posts designed to control traffic flow, protect pedestrians, and prevent vehicle-ramming attacks on buildings.

Proper installation by experienced bollard installation contractors ensures they meet necessary safety standards and provide maximum protection. They must be structurally sound and anchored correctly into the foundation to function as a safety barrier.

Similarly, architectural features demand specialized custom fabrication metal skills. When you need a custom-fit canopy over a loading dock, a series of attractive, weather-proof awnings oklahoma city for a retail strip, or a unique custom shelters for an outdoor seating area, the fabrication must be exact.

This process goes beyond simple welding; it requires precision cutting, forming, and finishing of architectural metal to create durable, aesthetically pleasing components that integrate perfectly with the existing structure.

Our ability to execute these specialized services, from canopy construction to intricate railing installation, highlights our versatility as a comprehensive metal contractor. We are experts in everything from redd iron work to fine-grain custom metal and fabrication.

FAQs About Structural Steel Fabrication

We want to make sure you have actionable knowledge about the core topic—structural steel—to help guide your decision-making process.

How does structural steel benefit the construction industry?

Structural steel is chosen for its unparalleled combination of strength, durability, and versatility. It offers an excellent strength-to-weight ratio, allowing for large, column-free spaces and open designs often required by commercial and industrial buildings. Furthermore, it is a sustainable material, being 100% recyclable, and its predictability in composition allows for precise engineering and faster onsite assembly compared to traditional materials.

How long does the structural steel fabrication process typically take?

The duration of the fabrication process varies dramatically based on the project’s size, complexity, and the contractor’s capacity. For a mid-sized commercial building, the detailing and shop drawing phase might take 2-4 weeks, followed by 4-8 weeks for cutting, shaping, and assembly in the fabrication shop. Working with a contractor who utilizes efficient, automated equipment (as mentioned in Question 5) and avoids outsourcing helps significantly in meeting aggressive timelines.

What is the difference between custom metal fabrication and welding?

Welding is a specific process—joining two materials (usually metal) by causing coalescence. It is a highly skilled trade. Custom metal fabrication is the comprehensive process of creating specialized metal products. It includes various steps like cutting, bending, machining, forming, assembly, and then welding. Welding is a tool used in the broader discipline of metal fabrication. A good metal fabrication shop employs welders, but also engineers, detailers, and fitters.

FAQs About Metal Contractors as a Business

Where does Metal Contractors provide its services?

Metal Contractors is proud to be a premier metal construction company based in Oklahoma City. We serve the entire OKC metro area and surrounding communities, focusing on a 50-mile radius that ensures we can provide timely, on-site support, including rapid mobile welding service near me dispatch. We are committed to supporting the local business community with the highest quality metalwork.

What is your primary specialization?

Our specialization lies in providing comprehensive, end-to-end metal construction services for commercial and high-end residential clients. This includes large-scale structural steel erection, precision custom metal fabrication, and installation of specialized architectural metal features like mezzanine floor contractors services, custom access platforms, bollards, and architectural awnings.

Does Metal Contractors work on repair and maintenance projects?

Yes, absolutely. We recognize that structures require upkeep. Our services include dedicated teams for metal building repair contractors work, encompassing everything from repairing damaged steel components to fortifying existing structures. Our mobile welding crews are often deployed for on-site repairs and maintenance, ensuring the longevity and safety of your metal assets. We aim to be your full-lifecycle partner in metal construction.

Meet the Experts

Experience, Expertise, Authority, and Trust

At Metal Contractors, we understand that trust is built on a foundation of verifiable competence and integrity. Our dedication to the four pillars of E-E-A-T—Experience, Expertise, Authority, and Trust—is woven into every project we undertake.

Experience: Since our founding, Metal Contractors has been involved in hundreds of commercial and industrial projects across Oklahoma City. Our portfolio includes everything from multi-story structural steel contractor projects to specialized bollard construction and customized canopy construction for major local businesses. We don’t just know metal; we know Oklahoma City construction.

Expertise: Our team is led by master welders and seasoned project managers. All our welders Oklahoma City professionals hold current certifications, including the critical AWS D1.1 standard for structural steel. We utilize in-house structural engineers and CAD detailers to ensure every piece of steel we fabricate meets precise specifications and all applicable local codes.

Authority: We are recognized as leading steel contractors and metal fabrication shop experts in the region. We regularly consult on complex structural issues and are compliant with all AISC (American Institute of Steel Construction) guidelines. Our facility and processes reflect an authoritative commitment to industry best practices, making us a trusted source for high-quality metal solutions.

Trust: Our commitment to transparent communication (as detailed in Question 7), rigorous safety standards (Question 8), and comprehensive post-installation warranties (Question 10) ensures we maintain a relationship built on trust with every client. When you choose Metal Contractors, you choose a partner dedicated to delivering exceptional quality safely, on time, and on budget.

Your Blueprint for Metal Construction Success

The success of your next commercial or industrial project in Oklahoma City hinges on the expertise of your structural steel contractor. By using these 10 definitive questions—focused on experience, capacity, certification (especially AWS D1.1 certification), and process transparency—you can confidently choose a partner that will deliver a structure of lasting quality and durability.

Metal Contractors is ready to be that partner. From intricate custom metal fabrication that gives your building a unique edge, to the deployment of our responsive mobile welding service near me for on-site efficiency, and the structural integrity provided by certified steel contractors, we manage every facet of your metal construction needs.

Don’t settle for less than the best. Contact us today to discuss your project, verify our credentials, and start building with confidence.