The OKC Blueprint: 7 Essential Questions to Ask Your Structural Steel Contractor Before Breaking Ground

You’re standing on the foundation of your next big commercial project, whether it’s a new warehouse, a custom retail space, or a specialized industrial facility. You know what you need: strength, durability, and a building that will stand for generations. In Oklahoma City, and across the 50-mile radius that surrounds it, that means relying on structural steel.

Structural steel is the backbone of modern construction. It’s a versatile material that provides superior load-bearing capacity, resistance to harsh weather, and fire safety. But before a single beam is lifted, you have to choose the right partner. Your choice of a structural steel contractor isn’t just about the lowest bid; it’s about securing an iron-clad commitment to safety, quality, and precision.

Choosing the wrong steel contractor can lead to budget overruns, crippling delays, and, worst of all, structural integrity issues. We’re here to give you the insider’s blueprint. We’ve broken down the most important questions—the ones that separate the true experts from the generalists—so you can hire with total confidence.

Use these 7 essential questions to vet any structural steel contractor near you.

Question 1: Do You Have Proven, Local Structural Steel and Custom Fabrication Expertise?

Hiring a contractor is not the time for on-the-job training. You need a partner with a robust, documented history in your specific type of project. This is the first, and most crucial, question to ask any potential metal construction company.

What is Your Experience with Projects like Mine?

A truly expert structural steelwork contractor will be proud to show you a diverse portfolio. They shouldn’t just show off pictures of finished buildings; they should talk about the complexities they overcame.

- Commercial Expertise: Have they successfully completed large-scale commercial metal building contractors near me projects, such as major retail centers or multi-story offices?

- Specialized Industrial Builds: Have they worked on facilities requiring precise, heavy-duty components, like custom shelters or extensive mezzanines?

- Architectural Accents: Can they point to instances where they blended functional structural work with high-end aesthetics, such as the installation of elaborate hand rail installers near me projects or complex architectural metal features?

Don’t be shy about asking for a local Oklahoma City client reference who had a similar scope of work. General construction experience is fine, but you need a specialist. A partner with deep roots in OKC will understand local codes, climate factors, and the specific material stresses required for structures in the area.

Beyond Steel: Do You Handle Related Services?

The best contractors are full-service partners. They don’t just put up the frame; they handle the crucial specialized elements that turn a structure into a usable space. This is where a top-tier metal fabrication shop near me shines.

For example, do they also handle:

- Mezzanine Installation: For warehouse and industrial clients, the ability to seamlessly integrate a load-bearing structure like a mezzanine floor is invaluable. Look for dedicated mezzanine floor contractors who understand material handling and safety standards.

- Site Security and Aesthetics: Can they install functional and safety-compliant elements like bollard installation contractors for vehicle protection, or elegant railing installation companies near me for stairs, platforms, and balconies?

- Exterior Protection: For business entrances and storefronts, do they have experience as awning contractors okc or canopy contractors? These structures require specialized engineering to withstand Oklahoma’s strong winds.

A partner that can manage the full scope of structural and custom metal fabrication work dramatically simplifies your project, reduces coordination errors, and ensures a consistent standard of quality across all metal components.

Question 2: Is Your Equipment and Technology State-of-the-Art?

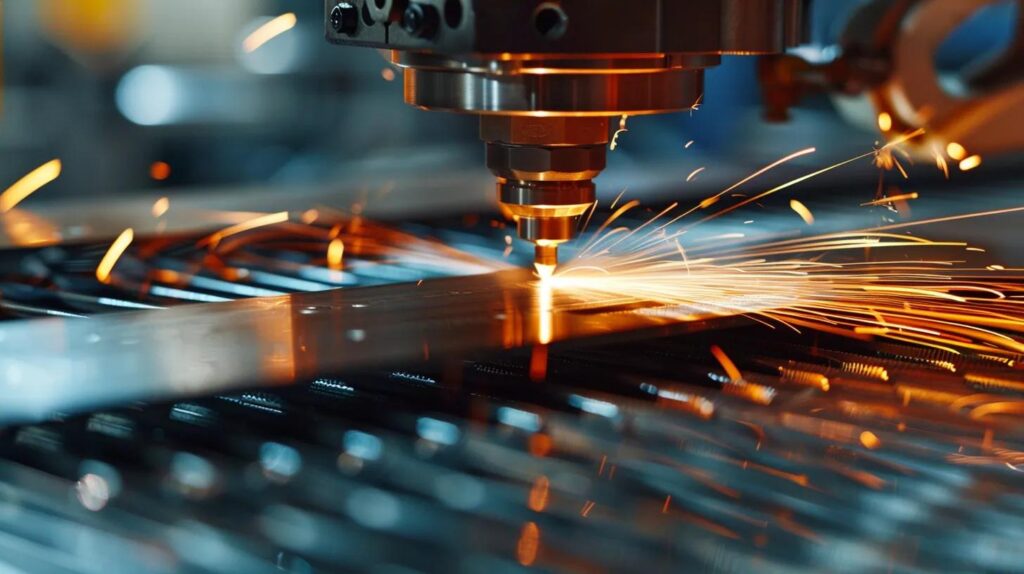

The precision of structural steel fabrication directly impacts the speed and cost of installation. Simply having an old warehouse with welding equipment isn’t enough; you need a modern metal fabrication shop running highly-accurate, automated equipment. This is a huge factor in minimizing your on-site build time and cost.

The Shop Tour: What to Look For in a Fabrication Shop

While you might not be an engineer, knowing the right buzzwords can help you judge a fabricator’s capabilities. Ask for a virtual tour, or even better, an in-person one. You are looking for proof of investment in precision.

- CNC Machinery: Does the shop utilize Computer Numerical Control (CNC) equipment? This includes CNC plasma cutters and high-capacity press brakes. CNC ensures every cut and bend is accurate to within a hair’s width, which is non-negotiable for load-bearing structural steel contractor work.

- High-Powered Cutting: Look for advanced laser cutting or high-definition plasma cutting equipment. These machines can cut through thick structural plate steel and sheet metal fabrication materials much faster and more cleanly than traditional methods, which is critical for meeting your project timeline.

- Robotic Welding: For repetitive components, the presence of robotic welding capabilities shows a commitment to consistency and volume. While a highly-skilled welding contractors team handles custom pieces, robotics ensures flawless, repeatable welds on high-volume parts.

Shops that invest heavily in their tooling are signaling that they take precision seriously. Poorly fabricated steel is the number one cause of costly on-site delays, where pieces don’t align perfectly. Insist on seeing the modern equipment that supports their custom fabrication metal work.

Question 3: How Does Your Team Ensure Safety and Quality Control?

Safety is not just a buzzword; it’s a measurable commitment that protects your project, your timeline, and your reputation. When dealing with heavy structural components, adherence to best practices is paramount. The right steel structure contractor will integrate safety and quality into every phase, from the shop floor to the final weld.

The Non-Negotiables: Safety Certifications and Training

Every structural steel and metal construction company should be able to provide clear evidence of their safety programs.

- OSHA and AISC Compliance: Ask about their safety record and their compliance with the Occupational Safety and Health Administration (OSHA) regulations. For steel, adherence to the American Institute of Steel Construction (AISC) standards is the gold standard, ensuring structural integrity and safety during the erection process.

- Comprehensive Fall Protection: Steel erection is high-risk work. Ensure they have a site-specific safety strategy that includes comprehensive fall protection systems, safety nets, and guardrails, far exceeding the bare minimum.

- The Ironworkers and Welders: Who is working on your site? Look for certified personnel. Specifically, your welders in okc should have American Welding Society (AWS) certifications. The riggers and ironworkers should also be certified and experienced in handling heavy, complex lifts. Qualified personnel are the difference between a high-quality connection and a potential structural weakness.

Material and Process: Quality at the Core

Quality control (QC) begins the moment materials arrive at the metal fabrication shop.

- Certified Materials: Inquire about their material sourcing. Are they using certified grades of carbon steel and structural plate? The use of substandard steel to save a few dollars is a massive liability.

- Inspection and NDT: The contractor should employ non-destructive testing (NDT) methods to verify welds and connections before they leave the shop. This includes visual inspection, dye penetrant testing, or ultrasonic testing to ensure every weld meets the required specifications and design tolerances. This rigorous, in-process inspection minimizes field corrections.

Question 4: Can You Manage Both Shop Fabrication and On-Site Services?

The scope of metalwork is vast, covering large-scale commercial builds and emergency repair jobs. A versatile contractor provides both. Their shop capacity is crucial for custom manufacturing, but their mobile capabilities are essential for installation, repair, and unexpected needs.

The Power of In-House Fabrication

When you need a custom solution—whether it’s custom metal fabrication near me, an access ladder, or an entire construction shelter—the work must be done right the first time.

In-house fabrication means the team designing your structure is the same team building it. They control the tolerances, the material quality, and the schedule. This is vital for complex elements like mezzanine floor builders work, where every piece must fit perfectly into an existing or new structural frame. An expert metal fabrication shop will not outsource their most complex custom fabrication metal work.

Rapid Response: Mobile Welding and Onsite Services

A major benefit of having a trusted, local steel structure contractor is their ability to deploy quickly. Installation often requires field modifications, touch-ups, and specialized joining.

- Mobile Welding Service Near Me: For repairs, modifications, or specialized onsite welding services, a dedicated mobile welding company can save days of downtime. This service is invaluable for tasks like:

- Repairing a fence or gate that was damaged on-site.

- Finalizing a structural connection that was left open for other trades.

- Emergency pipe or hand rail installers repairs.

- Repairing a fence or gate that was damaged on-site.

- Finalizing a structural connection that was left open for other trades.

- Emergency pipe or hand rail installers repairs.

Ask about their fleet. A reputable mobile welding shop should be fully equipped for any task, bringing not just a welder, but a portable welding rig and all necessary equipment directly to your Oklahoma City job site. This on-site capacity, paired with their in-house metal fabrication capabilities, is a strong indicator of an efficient, full-service operation.

Question 5: What Are Your Best Practices for Commercial Installation?

A project’s success is determined by the planning that happens before the steel arrives. A premier structural steel contractor doesn’t just show up with a crane; they coordinate the entire erection sequence with military precision.

Pre-Planning and Coordination—The "Blueprint" Step

Before any material leaves the metal fabrication shop, the contractor should have a detailed plan. This plan acts as the OKC Blueprint for the project.

- Site Logistics: They must assess the job site for terrain, access, and staging areas for the steel. The material should be delivered and staged in an order that matches the erection sequence (just-in-time delivery).

- Erection Sequence: They should have a step-by-step sequence developed in coordination with the project engineer. This sequence ensures stability at every stage.

- The Personnel Schedule: They must staff the site correctly. Initial lifts require more riggers and signalers, while later phases depend on finish welders in okc and ironworkers for detailing and final connections.

Managing the Project and Minimizing Trade Conflicts

Commercial construction is a complex ballet of different trades. The metal construction company must be a team player. They should demonstrate their strategy for integration with other systems.

- MEP Integration: The plan must account for Mechanical, Electrical, and Plumbing (MEP) systems. Have they planned for penetrations through beams or the integration of rooftop unit framing supports before the steel is bolted?

- Sequencing with Concrete/Floors: Steel erection must be carefully sequenced with concrete crews pouring footings and slabs. The plan must detail when metal decking is installed and when concrete floors can be poured to ensure a safe, stable working platform for later trades.

This meticulous pre-planning and coordination are what allow the project to move forward smoothly, minimizing costly conflicts and ensuring the final structure is plumb, square, and within the tight tolerances required for commercial steel construction.

Question 6: Do You Offer Design and Engineering Support?

The days of simply following a blueprint are over. The most forward-thinking steel structure contractor can offer design input that saves you time and money before fabrication even begins.

The Value of Design for Manufacturability (DFM)

This is a critical, value-added service. Design for Manufacturability (DFM) means that the fabricator reviews the engineer’s drawings not just for structural integrity, but for ease and efficiency of production.

A good custom metal fabrication near me expert can flag potential issues early in your collaboration:

- Simplifying Complex Welds: They might suggest a slight design change to replace a difficult, costly field weld with a simpler, more efficient shop-fabricated bolted connection.

- Material Optimization: They can ensure that material cuts minimize waste, which directly lowers your material cost.

- Logistics Check: They’ll verify that the designed components are sized and shaped appropriately for efficient transport to your Oklahoma City job site.

By leveraging their in-the-field expertise, a fabricator with engineering support acts as a crucial check on the design, ensuring that the finished product is not only structurally sound but also manufactured as efficiently as possible. This is the difference between an expensive build and a smart build.

Question 7: How Do You Calculate Costs and Guarantee Timeliness?

The final question addresses the bottom line. Transparency in pricing and a track record of meeting deadlines are non-negotiable.

The Transparent Quote (Avoiding the Cheapest Bid Trap)

While cost is important, selecting a metal construction company based only on the cheapest quote is often a recipe for disaster. The low-cost provider may be cutting corners by:

- Using cheaper, uncertified materials.

- Lacking the modern, efficient equipment mentioned in Question 2.

- Failing to carry adequate insurance or offer strong warranties.

A professional contractor will provide a detailed quote that clearly breaks down material costs, shop fabrication labor, and on-site erection costs. They should be able to explain how their expertise, equipment, and certified crew justify their price, delivering superior value and a lower risk of costly, schedule-crippling errors.

Finally, ask for their average turnaround time for projects of your scope. A professional, organized structural steel contractor uses project management software and clear communication to meet—or even exceed—their scheduled deadlines, giving you a reliable partner you can count on in Oklahoma City.

Build with the Best Metal Construction Company in OKC

Your commercial project is a massive investment, and its long-term success hinges on the quality of its structural steel. By asking these seven questions, you are doing more than vetting a vendor—you are qualifying a true partner.

You need a company that offers the full spectrum of services: meticulous metal fabrication shops work, dependable mobile welding service near me capabilities, an iron-clad commitment to safety and quality, and deep expertise as structural steel contractors.

At Metal Contractors, we don’t just build with steel; we build relationships forged in trust and precision. We are your local OKC experts, ready to bring your vision to life with the quality and accountability you deserve. Let’s start building your future today.

FAQs About Structural Steel Contractors

What are the main benefits of choosing structural steel over other building materials?

Structural steel is incredibly strong, durable, and lightweight compared to concrete, often reducing the size and cost of foundations. It is versatile, easy to assemble, and 100% recyclable, making it an environmentally-friendly choice. Its long, column-free spans allow for greater flexibility in interior design, which is essential for commercial and industrial structures.

What types of structures require a certified structural steel contractor?

Any large-scale structure that requires heavy load-bearing capacity benefits from a certified structural steel contractor. This includes, but is not limited to, commercial office buildings, industrial warehouses, parking garages, bridges, high-capacity mezzanines, and large commercial metal building contractors near me projects. Even smaller custom jobs like heavy-duty access platforms or elaborate architectural canopies should rely on this expertise.

What is the most common challenge in structural steel fabrication or installation?

The most common challenge is ensuring absolute accuracy and precision in the fabrication shop. If the steel members are not cut, shaped, and welded perfectly to spec, they will not align correctly on-site. This leads to costly field rework and significant project delays. This is why it is critical to use a metal fabrication shop near me with state-of-the-art CNC equipment and rigorous in-house quality control.

What are construction bollards and why do metal contractors install them?

Construction bollards are short, vertical posts made of steel or concrete, often filled with concrete and secured into the ground. They are installed by bollard installation contractors primarily for safety and security. They prevent accidental or malicious vehicle impacts on storefronts, utility equipment, or pedestrian walkways. Bollards require precise installation to ensure they can withstand high-impact forces.

FAQs About Metal Contractors

Frequently Asked Questions About Metal Contractors

What specific metal construction services do you offer in Oklahoma City?

Metal Contractors offers a comprehensive range of metal construction services for both residential and commercial clients in Oklahoma City and the surrounding 50-mile area. Our services include: full-service custom metal fabrication, structural steel erection, mobile and onsite welding services, installation of access ladders, platforms & mezzanine floor contractors work, custom railing, and architectural features like awning contractors okc and canopies.

Do Metal Contractors handle both commercial and residential projects?

Yes, we are equipped to handle projects of all sizes. While we are experts in large structural steel contractor work for commercial and industrial clients, we also serve residential clients with custom metal needs, such as decorative railings, specialized gates, fencing, and custom metal fabrication projects for home workshops and renovations.

What is the typical warranty you offer for your structural work?

For our structural steel and major commercial fabrication projects, we typically offer a warranty ranging from 5 to 10 years, depending on the specific scope and materials used. We stand behind our work, using only certified materials and adhering to the highest industry standards to guarantee superior, long-lasting results. We will discuss the specific warranty terms for your project during the initial consultation.

Do you provide an estimate for your services?

Yes, Metal Contractors provides personalized consultations and free, detailed estimates to get your project started. We believe in transparency and providing accurate pricing that accounts for material quality, certified labor, and the scope of work. Contact us today to discuss your next construction or metal fabrication project in the Oklahoma City area.

About Metal Contractors: An Oklahoma City Staple of Excellence

An Oklahoma City Staple of Excellence

Author & Company Credentials: This blog post was authored by the expert team at Metal Contractors, Oklahoma City’s premier provider of professional metal construction and custom metal fabrication services.

Our Experience and Expertise (E & E): Since our founding, Metal Contractors has been dedicated exclusively to the trade of metal construction, welding, and structural steel contractor services. This singular focus has allowed us to accumulate deep, specialized expertise in complex builds, from multi-story commercial steel frames to highly specialized mezzanine floor contractors and bollard installation contractors projects.

Our team is composed of licensed steel contractors, certified welders in okc (AWS certified), and seasoned ironworkers who bring decades of combined experience to every job site. We operate a state-of-the-art metal fabrication shop fully equipped with CNC and laser-cutting technology, guaranteeing precision that meets the most demanding engineering specifications.

Our Trustworthiness and Authoritativeness (T & A): We are a fully licensed and insured metal construction company operating under the highest safety protocols (OSHA compliant) and industry standards (AISC compliant). Our commitment to quality is proven by our portfolio of successful commercial metal building contractors near me projects across Oklahoma City and the surrounding region.

We prioritize clear communication, transparent pricing, and adherence to schedules. When you partner with Metal Contractors, you choose an established local business that has earned its reputation by delivering superior, durable metal creations and providing expert mobile welding service near me for all on-site needs. We are dedicated to the growth and safety of the Oklahoma City community.